病毒疫苗生产

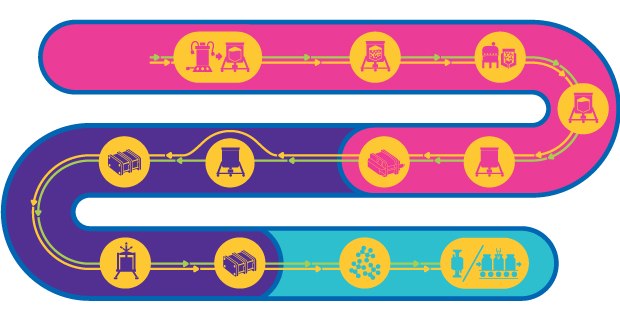

灭活和减活病毒的流程列车

特色类别

我们现成可用的细胞系系统大大减少了开发新细胞系的时间、成本和风险。无论您是在生产抗体、重组蛋白、疫苗还是用于基因治疗的病毒载体,我们的细胞系平台都能加速您的上游进展。

我们的细胞系系统可大大降低开发新细胞系的时间、成本和风险。

通过可靠的放大优化上游生产率和澄清

为生产病毒疫苗而开发的上游培养工艺必须经过优化,以满足生产率要求。这种优化包括澄清步骤,该步骤对于去除细胞和细胞碎片以及确保稳健的病毒收获至关重要。

通过稳健的杂质去除实现产量和效率目标

裂解细胞中的核酸是病毒疫苗工艺中常见的污染物。法规要求减毒疫苗中宿主细胞核酸的携带量必须低于 10 纳克/剂量。Benzonase® 内切酶处理和切向流过滤是降解和去除残留核酸成分的强大组合。

最大化下游回收

在浓缩和重滤过程中,苯甲酰酶®内切酶处理足以使大多数病毒疫苗达到理想的纯度水平。但是,要达到日本脑炎病毒 (JEV) 和登革热病毒 (DENV) 等下一代病毒疫苗的纯度目标,则需要色谱法。由于每种生产工艺都必须根据病毒的特性量身定制,因此下游纯化的工具箱对于在确保最佳回收率的同时达到所需的纯度至关重要。

确保患者安全

尽管病毒疫苗是使用减毒病毒生产的,但确保患者的安全仍然是一个重要问题。病毒疫苗的最终体积与水相当。因此,在最终配制和灌装完成步骤之前,可使用 0.22 µm 灭菌过滤对疫苗进行灭菌。

生物处理液体细胞培养基和缓冲液

我们提供业界最高质量的无菌过滤液体,从全球的 GMP 工厂供应即用型细胞培养基、缓冲液、CIP 和 SIP 产品,以优化您的生物制药生产。

最终无菌过滤和灌装

消除产品交叉污染问题,同时简化灌装-精加工要求并符合当前的监管要求。

相关文章

- Adjuvant selection for vaccine formulation considers safety, effectiveness, and other characteristics for optimal application.

- Influenza vaccines are commonly made using egg-based and cell-based manufacturing strategies. Find step-by-step information on the manufacturing process for each method.

- Cost Modeling Vaccine Manufacturing: Estimate Production Costs for mRNA and other Vaccine ModalitiesA custom-designed cost model is used to explore the economics of vaccine manufacturing across several different modalities including mRNA. The model enables greater process understanding, simulates bottlenecks, and helps to optimize production efficiency.

- Learn more one the attenuated viral vaccines manufacturing process: cell culture, clarification, nuclease treatment, chromatography, and sterile filtration.

- 查看全部 (12)

相关资源

- Application Guide: Biopharmaceutical

A search tool to help you overcome your manufacturing challenges.

- Brochure: Vaccine Bioprocessing Handbook

In this handbook, we explain the vaccine production processes and process improvements for all types of vaccine development platforms.

- Mini-Handbook: Cell-Based Vaccine Bioprocessing

Live attenuated viral vaccines can be created using a complex, multi-step cell-based manufacturing process. It is not a templated process. The manufacturing process for each viral vaccine is different.

- e-Book: Enabling Capabilities & Solutions for all Vaccine Platforms

From process development to full-scale GMP-manufacturing, our global vaccine capabilities can help you achieve these goals for all your modalities/platforms including virus-based, subunit, VLP, viral vector, pDNA and mRNA vaccines.

- White Paper: Filtration Strategies for Optimal Development and Purification of a Foot and Mouth Disease Virus

We collaborated with MEVAC to optimize upstream and downstream processes for FMD vaccine manufacturing to establish a scalable, cost-efficient and GMP compliant process. This white paper focuses on the integration of new filtration strategies in both upstream and downstream processes.

- White Paper: Downstream Process Intensification for Virus Purification Using Membrane Chromatography

This white paper provides an overview of the challenges presented by current approaches to virus production and the opportunities to develop a platform approach that can work across different viral modalities and accelerate process development.

- Application Note: Effect of Benzonase® Endonuclease Addition to Purification of Sabin Polio Virus Type 3

This application note summarizes the benefits of incorporating Benzonase® endonuclease in a polio virus type 3 production process.

- Article: Filter-Based Clarification of Viral Vaccines and Vectors

In this article, a comprehensive overview is provided on different filtration technologies and their application in viral vaccine clarification, outlining challenges and present current best practices.

查找更多文章和协议

我们能提供哪些帮助

如有任何问题,请提交客户支持请求

或与我们的客户服务团队沟通:

发送电子邮件custserv@sial.com

或致电 +1 (800) 244-1173

额外支持

- 计算器与应用_缓冲液计算器_HPLC方法转换计算器-默克生命科学

默克该工具箱包括用于化学、生命科学、材料科学等方面的科学研究工具和资源。

- Customer Support Request

Customer support including help with orders, products, accounts, and website technical issues.

- FAQ

Explore our Frequently Asked Questions for answers to commonly asked questions about our products and services.

如要继续阅读,请登录或创建帐户。

暂无帐户?