Ultrapure Water for Sensitive LC-MS Analysis of Pesticides

The aim of the study was to illustrate the efficiency of Milli-Q® water purification systems in eliminating pesticides from tap water, and thereby producing and delivering reliable and consistent-quality ultrapure water suitable for pesticides analysis. The results obtained from spiked solutions containing challenging concentrations of pesticides demonstrated that the integrated technologies within Milli-Q® water purification systems effectively contribute to the removal of pesticides. None of the pesticides analyzed was detected in the samples tested using LC-MS/MS, with limits of quantification (LOQ) set at 0.01 or 0.05 µg/L, depending on the specific pesticide. These findings underscore the suitability of Milli-Q® ultrapure water for the analysis of pesticides and other organic compounds by chromatography techniques.

Section Overview

- Impact of Pesticides on Environment and Human Health

- Regulatory Framework and Quality Control

- Role of Ultrapure Water in Pesticide Analysis

- Study: Evaluation of a Milli-Q® Water Purification System to Remove Pesticide Residues

- Results & Discussion: Pesticides Analysis in Pure & Ultrapure Water

- Comprehensive Water Purification Solutions for Pesticide Analysisy

- Experimental Procedure

- Related Products

Impact of Pesticides on Environment and Human Health

Pesticides include herbicides, fungicides, insecticides, acaricides, plant growth regulators and repellants. Pesticides also cover products such as biocides for non-plant uses to control pest and disease carriers. These substances can persist in the environment, bioaccumulate throughout the food chain, and potentially induce adverse effects on human health and other organisms.

Numerous studies have revealed the potential detrimental impact of pesticides on non-target organisms. For example, certain pesticides, such as neonicotinoids,1,2 like clothianidin, imidacloprid and thiamethoxam, were found to be associated with environmental and health risks and were therefore prohibited from outdoor use in 2018 in the EU. Monitoring pesticide levels is crucial for controlling their misuse and environmental repercussions, and ensuring public health and safety. This was exemplified by the detection of fipronil, a potentially harmful insecticide, in eggs, egg products and chicken across 15 EU countries in 2017.3

Regulatory Framework and Quality Control

Pesticide regulations vary across countries, as highlighted in a study that reported that a quarter of pesticides authorized in the US are banned in the EU.4 For the purposes of this discussion, EU regulations will be referred to, as they are considered the most stringent worldwide.

Quality control laboratories monitor pesticides in food, soil and water in compliance with regulations. For food analysis, many laboratories adhere to EU Regulation No 396/2005, which sets the authorized maximum residue levels (MRLs) for pesticides in food and feed.5 For water analysis, the Water Framework Directive (2000/60 EC) is the primary legislation in Europe that establishes a framework for community action in the field of water policy (e.g., monitoring, management, and strategies for the prevention and control of groundwater pollution).6

Role of ultrapure water in pesticide analysis

Pesticide analysis is performed using LC-MS (Liquid Chromatography-Mass Spectrometry) and GC-MS (Gas Chromatography-Mass Spectrometry). The technique selected is based on the physicochemical properties of the molecules under investigation. For example, non-polar pesticides are analyzed using GC-MS in drinking water according to the ISO/TS 28581:2012 standard.7 Organochlorine pesticides are analyzed using GC-MS in drinking, ground, surface water and wastewater in accordance with the ISO 6468:1996 standard.8 Other methods, such as E_FP417.1, involve the use of LC-MS for the determination and quantification of pesticides, metabolites and isomers in cereals and cereal products.9

Depending on the technique, water may serve as a blank, a mobile phase component, and/or for the preparation of samples, standards and calibration solutions. Using high-quality water is therefore imperative to assure consistent and results reliability. Laboratories, especially accredited ones, aim to select high-quality water purification systems that deliver consistent-quality water and that actively monitor and record quality parameters. This facilitates their routine quantification, screening analyses and traceability, and assures their reliability, productivity and efficiency.

Study: Evaluation of a Milli-Q® Water Purification System to Remove Pesticide Residues

Studies indicated the presence of pesticides in drinking water,10 which could impact tap water feeding water purification systems in testing laboratories. Aware of the challenges faced by analytical laboratories to assure reliability and consistency of their analyses, we conducted a study to demonstrate that Milli-Q® ultrapure water systems can deliver water that is suitable for sensitive analytical experiments thanks to the presence of high-performance purification technologies, even when challenged with pesticide-contaminated water.

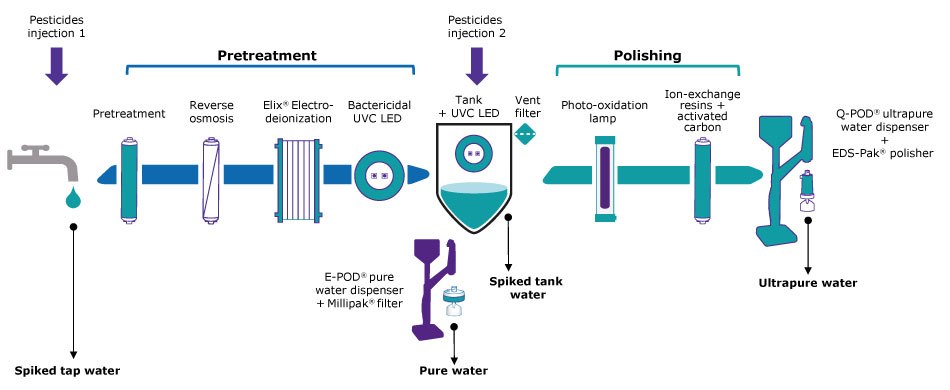

To ascertain if tap-to-pure water and tap-to-ultrapure water systems remove pesticides, two different challenges were performed at two stages of the purification process (Figure 1). Tap water (Pesticide injection 1) and water in the tank (Pesticide injection 2) were each spiked with a doping solution containing approximately 1 µg/L (approximately 100 times the MRL of most pesticides11) of 17 pesticides (Pestanal® analytical standard). The standard was composed of the following 17 pesticides: atrazine, atrazine-desethyl, cyanazine, sebuthylazine, simazine, cyanazin, sebuthylazin, simazine, terbuthylazine, hexazinon, chlortoluron, diuron, isoproturon, linuron, methabenztiazuron, metobromuron, metoxuron, monolinuron, metazachlore, metolachlor. Of note, sebuthylazin was not analyzed in this study. Pestanal® standard was selected because it contains triazine and urea family compounds, commonly tested in food, beverages and environmental samples, and are reported as highly toxic compounds.

We chose to use the EDS-Pak® polisher at the Q-POD® point-of-dispense of a Milli-Q® IQ 7 series ultrapure and pure water system. This polisher contains a specific type of activated carbon that has been validated to remove organic contaminants, including several endocrine disruptors (EDs).

Water samples were collected after the pretreatment and polishing steps of the water purification process and sent for LC-MS/MS pesticides analysis to a third-party accredited testing laboratory. Analyses were performed according to methods described at the end of the article in experimental procedure section. Analyses were performed in duplicates.

Figure 1.Experimental set-up depicting the technologies in a Milli-Q® IQ 7015 water purification system. Arrows indicate where the pesticide doping solution was injected (in the tap and tank water) and the four samples that were analyzed [(1) spiked tap feed water, (2) pure water produced after the pretreatment step, (3) spiked water in the tank before the polishing step, and (4) ultrapure water produced after the polishing step withdrawn at the point-of dispense equipped with an EDS-Pak® polisher].

Results & Discussion: Pesticides analysis in pure & ultrapure water

Pretreatment Step: From Tap Water to Pure (Type 2) Water

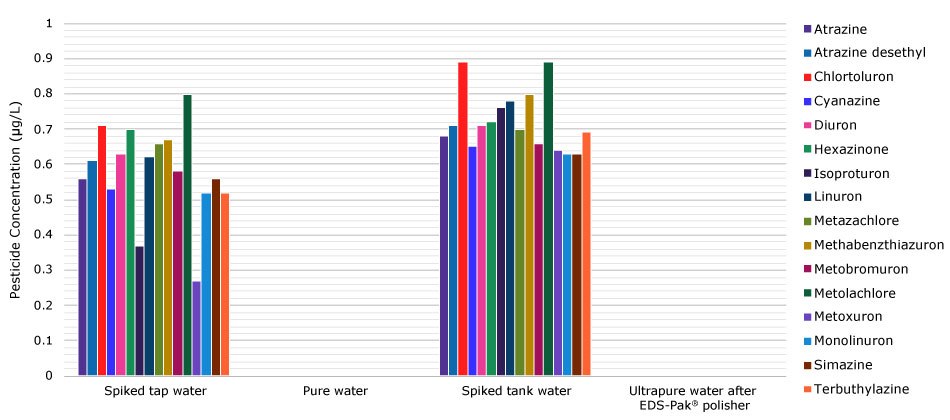

The results of LC-MS/MS analysis showed that none of the pesticides tested could be quantitatively detected in the pure water obtained during the pretreatment stage (Table 1 and Figure 2, left sides). The LOQ was between 0.01 and 0.05 µg/L, depending on the pesticide under investigation.

Pesticides were likely primarily adsorbed by activated carbon within the pretreatment cartridge. Activated carbon has a porous structure which provides a large surface area where molecules can be adsorbed due to intermolecular interactions, such as Van der Waals forces. Additionally, the very small pore sizes of the reverse osmosis semi-permeable membrane likely contributed to the removal of pesticides.

Polishing Step: From Pure (Type 2) to Ultrapure (Type 1) Water

Although the concentrations of pesticides were found to be below the LOQ in pure water, the polishing step is nevertheless essential to remove trace organic and inorganic contaminants, ensuring that high-quality ultrapure water is used for sensitive analyses, such as LC-MS/MS.

As many labs may not be equipped with this same efficient water pretreatment process consisting of activated carbon, reverse osmosis and Elix® EDI, we therefore also assessed whether the combination of technologies within the polishing step of a Milli-Q® IQ 7 purification system (Figure 1, right side) could efficiently remove pesticides from contaminated pure water. To this end, we introduced the pesticide doping solution into the tank, then analyzed the spiked tank water and freshly dispensed ultrapure water that had passed through an EDS-Pak® polisher.

LC-MS/MS analysis indicated that the concentration of each pesticide was below the LOQ in the freshly obtained ultrapure water (Table 1 and Figure 2, right sides). Based on these data, we conclude that the combination of technologies involved in the production of ultrapure water from pure water in a Milli-Q® IQ 7 series water system results in freshly-produced water exempt of the pesticides under investigation in these conditions of analysis.

Figure 2.Pesticide concentrations in four water samples after different water purification steps. Specifically, from left to right, spiked tap water, pure water after pretreatment, spiked pure water in the tank, and freshly-dispensed ultrapure water after polishing that included an EDS-Pak® polisher.

Comprehensive Water Purification Solutions for Pesticide Analysis

This study provides evidence that the purification technologies embedded in Milli-Q® IQ 7 series water systems [i.e. Milli-Q® IQ 7003/7005/7010/7015 (tap to pure to ultrapure) and Milli-Q® IQ 7000 (pure to ultrapure)], plus EDS-Pak® polisher at the point of dispense, enable the effective removal of pesticides even in challenging conditions.

The high-quality ultrapure water obtained from Milli-Q® IQ 7 series systems is well-suited for critical analytical experiments, even in geographical locations where tap water may contain pesticides. Quality control laboratories engaged in the analysis of pesticides in drinking water, fruits and vegetables, medicinal plants, environmental samples, among other type of samples, can confidently rely on a benchtop Milli-Q® IQ system with an EDS-Pak® at the point-of-dispense to ensure no detectable amounts of pesticides will be present in the ultrapure water used for their analysis.

A range of water purification solutions are available to meet the needs of scientists analyzing pesticides and working in environmental and food and beverage testing laboratories.

Experimental procedure

Analyses were performed by a third-party accredited laboratory (Laboratoire GIRPA, Beaucouzé, France).

Analysis by Direct Sample Injection

Samples were analyzed on the day of reception. Samples were manually homogenized for 30 seconds and diluted, if necessary, according to internal procedure. Calibration curves are obtained in a range of 0.1 to 50 µg/L. The samples were injected using the parameters described in Table 2.

Analysis of Concentrate Samples

Pesticides were extracted with 3 successive extractions using 80/20 dichloromethane/ethyl acetate solution. The pH was adjusted to 7 using a 10 M sodium hydroxide solution, and the organic phase was collected. An 85% orthophosphoric acid solution was added to the aqueous phase. Extraction tracers were added to the mixture to quantify the dosage, then 30 g of sodium chloride were added in 500 mL of the solution. All fractions were gathered and placed at -18 °C to remove any trace of water using a mechanic filter. The solution was concentrated using a rotavapor and an aliquot was added to a solution of 50/50/0.1 v/v/v ultrapure water/methanol/acetic acid (by exchange with ethyl acetate using a flux of nitrogen) for LC-MS/MS analysis. Internal standards were added to ensure precision, correctness and accuracy. Table 3 presents the parameters used for the LC-MS/MS analysis.

Related Products

References

如要继续阅读,请登录或创建帐户。

暂无帐户?