Evaluation of Spheroid Formation and Robustness using Millicell® Ultra-low Attachment Plates

- Scaffold-Free 3D Cell Culture Methods

- Millicell® Ultra-low Attachment Plates

- Spheroid Formation and Robustness Analysis Protocol

- Spheroid Formation Results

- Spheroid Roundness Analysis

- Spheroid Circularity Analysis

- Materials

Scaffold-Free 3D Cell Culture Methods

3D cell culture is an important in vitro alternative to traditional 2D cell culture. In some cellular research applications such as cancer studies, regenerative medicine, and experimental drug discovery, 3D models can be more relevant as they closely replicate in vivo structures. Common 3D experimental models can be split into two different methods - scaffold-based and scaffold-free methods.

In the scaffold-free method, cells are not grown on any physical supports such as hydrogels or structural scaffolds. Because of the lack of scaffolds, the cell lines form 3D cellular aggregates called spheroids. This method allows cells to directly interact with their substrates, other cells, and the extracellular matrix (ECM) in all directions. The spheroids are often used by researchers to screen compounds in high-throughput drug development and toxicology studies.

Millicell® Ultra-low Attachment Plates

The Millicell® Ultra-low Attachment (ULA) Plates are coated with a unique ultra-hydrophilic polymer. The plates promote the self-assembly of uniform spheroids in a scaffold-free, high-throughput environment. The ergonomic plates contain U-bottom wells that allow for in assay manipulation such as fixing and staining.

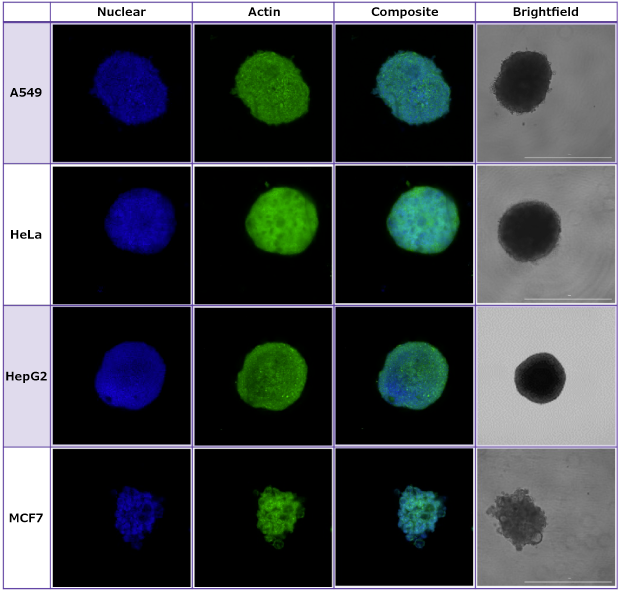

Millicell® ULA plates also have high optical clarity and are thus suitable for both brightfield imaging and confocal microscopy. However, confocal imaging directly at above 20x magnification in the U-bottom plate is not recommended, as the U-bottom negatively impacts focal plane flatness at higher magnification.

Here we demonstrate how to use the Millicell® ULA plates to calculate the circularity and roundness of spheroids during a spheroid formation assay.

Figure 1.Millicell® Ultra-low attachment plate. The plate has a frosted surface to improve plate reading and fight light glare, and numbering on the top and bottom of the plate to easily navigate in 96-wells.

Spheroid Formation and Robustness Analysis Protocol

1. Seed the cell lines A549, HeLa, and MCF7 the into clear Millicell® ULA U-bottomed 96-well plates at 5,000 cells per well.

2. Allow cells to grow and divide for 24-72 hours.

3. Perform brightfield and phase imaging to confirm single spheroid formation at the time points 24 hours, 3 days, 5 days, and 7 days. For this protocol, brightfield imaging was performed on BioTek Lionheart automated microscope.

4. Determine and quantify the area, roundness, and circularity of each spheroid. Spheroid area was calculated in ImageJ based on the pixels/µm2 within the spheroid.

5. Evaluate spheroid formation at 7 days using confocal imaging in the Millicell® ULA U-bottomed 96-well plates at 10X and 20X magnification.

Figure 2.Spheroids were imaged using brightfield and confocal microscopy to demonstrate the optical clarity of the Millicell® ULA plates.

Spheroid Formation Results

The spheroids formed successfully and grew at similar rates in both the Millicell® ULA and control plates. A549 cell lines formed loose spheroids and required a few days to contract and compact before forming a full spheroid. Both HeLa and MCF7 cell lines grew more linearly, forming spheroids within 24 hours of plate seeding. There were no significant differences between spheroid formation in the Millicell® ULA and control plates via Wilcoxon T test for paired non-parametric data (P>0.05).

Figure 3.Spheroid formation in Millicell® ULA plates compared to the control plate. A) A549 cells; B) HeLa cells; C) MCF7 cells. There is no significant difference between spheroid formation for the cell lines.

Spheroid Roundness Analysis and Results

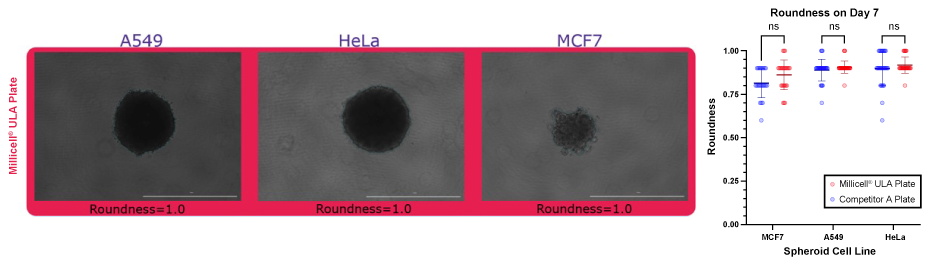

The roundness of a spheroid is a common method used in the literature to quantify and analyze spheroid shape and formation. Spheroid roundness is often used to indicate how compact the spheroid formed and to monitor ECM formation around the spheroid in the well. The roundness of a spheroid may decrease over the lifetime of the spheroid.

Our roundness quantification method uses the region of interest designated in ImageJ to quantify how round the spheroid is for use in further analyses. The calculation shown below compares spheroid area to the maximum area that is calculated based on the longest diameter of the spheroid. Using this calculation, perfectly round spheroids will have a roundness at or near 1. There is no significant difference in spheroid roundness between the Millicell® ULA and control plates for all cell types (Figure 4).

Figure 4.Brightfield imaging showing spheroid roundness for spheroid forming cell lines. A) A549 cell line spheroid; B) HeLa cell lines spheroid; C) MCF7 cell line spheroid; D) Quantification of spheroid roundness between the Millicell® ULA and control plates.

Spheroid Circularity Analysis

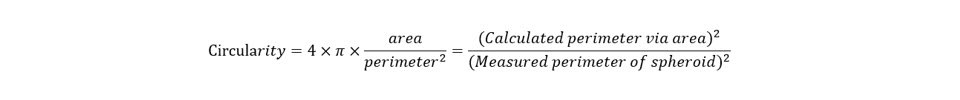

Another common method for evaluating spheroid formation is to monitor spheroid circulatory. Spheroid circularity is used to analyze the spheroid for the smoothness of the spheroid surface. Like spheroid roundness, quantifying and analyzing spheroid circularity is used to indicate how compact the spheroid is and help evaluate ECM secretions by the spheroid.

For rougher or bumpier spheroids, such as the MCF7 cell line, will have a lower circularity value because the perimeter of the spheroid is longer than the perimeter of a smoother spheroid, such as the HeLa cell line. Using the calculation shown below, spheroids that were formed using the Millicell® ULA plates had equivalent circularity with spheroids that formed in the control plate. The spheroids formed in the Millicell® ULA have a roundness value between 0.6 and 0.8 (Figure 5).

Figure 5.Brightfield imaging showing spheroid circularity for spheroid forming cell lines. A) A549 cell line spheroid; B) HeLa cell lines spheroid; C) MCF7 cell line spheroid; D) Quantification of spheroid circularity between the Millicell® ULA and control plates.

Related Materials

如要继续阅读,请登录或创建帐户。

暂无帐户?