description

Electrodes, Silver content:18-20%W/W

form

liquid

color

dark gray

mean particle size

85-105 nm

surface tension

36.0-44.0 mN/m

viscosity

12.5-18.5 mPa.s (25 °C, shear rate 1000 s-1)

density

1.3 g/mL

storage temp.

2-8°C

General description

Highly conductive silver ink for Printed Electronics applications on flexible substrates. The low resistivity is resulting from the fusion of the metallic nanosilver particles during the sintering process.

Key Benefits

Typical Properties of Printed and Sintered Product

Single pass printed with KM1024i LHE on PowerCoat® HD1 and sintered with NIR lamp.

Key Benefits

- Low volume resistivity

- Compatible with several sintering methods

- Good adhesion on coated and synthetic papers, treated and untreated PET

- Support for industrial print heads

- High stability and easy handling

Typical Properties of Printed and Sintered Product

Single pass printed with KM1024i LHE on PowerCoat® HD1 and sintered with NIR lamp.

- Resistivity <3 mW//25μm

- Dry Film Thickness 1-2 μm

- Printing resolution 150 μm lines & gaps

- Adhesion 0-1 (ISO 2409 crosshatch test, no material removal)

Application

Conductive nanosilver inks are made up of silver nanoparticle colloids and suspensions, which are majorly used in printed electronics. Their applications include flexible displays, printed circuit boards, solar cells, and disposable electronics.(3)

Legal Information

PowerCoat is a registered trademark of Arjo Wiggins Fine Papers Ltd

Disclaimer

Basic Processing Guidelines

To clean the print head after use, proceed in reverse order.

The above printing and sintering conditions are guidelines. Conditions may vary based on customers′ experience and their application requirements, as well as customer printing and drying equipment.

- For prolonged shelf life, store between 0 and 4°C. Under typical jetting conditions, the ink will remain stable for one week.

- Tested print heads are KM1024i LHE, Q-class Sapphire, DMC11610 (disposable cartridge)

- Print head temperature between 25 and 35 ºC

- Substrate temperature between 25 and 60 ºC

- Sintering in ventilated box oven 150 ºC for 30 minutes. Higher sintering temperatures result in higher film conductivities and lower dwell times. Best results on paper have been obtained with NIR lamp

- To avoid contamination from other inks before loading the print head with silver ink, it is recommended to flush with ethanol first, then flushing with the associated cleaning solution SI-JCS1, and then load the silver ink.

To clean the print head after use, proceed in reverse order.

The above printing and sintering conditions are guidelines. Conditions may vary based on customers′ experience and their application requirements, as well as customer printing and drying equipment.

signalword

Danger

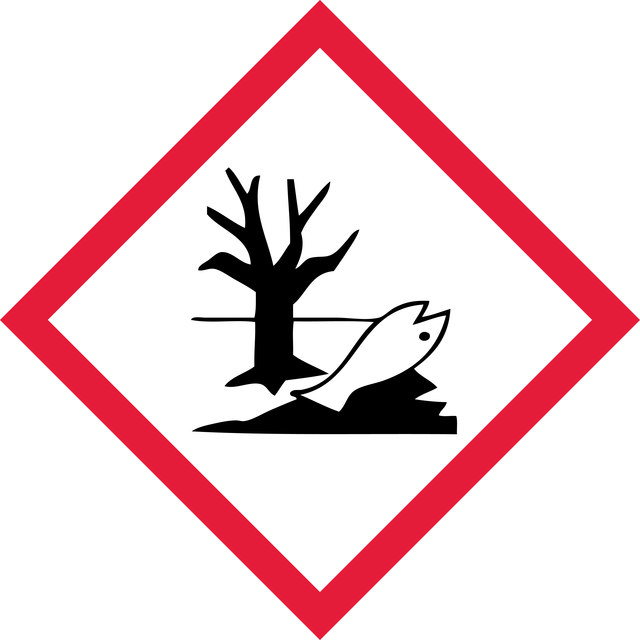

hcodes

Hazard Classifications

Aquatic Acute 1 - Aquatic Chronic 1 - Eye Dam. 1 - Repr. 1B - STOT SE 3

target_organs

Respiratory system

存储类别

6.1C - Combustible acute toxic Cat.3 / toxic compounds or compounds which causing chronic effects

wgk

WGK 3

flash_point_f

>230.0 °F

flash_point_c

> 110 °C

Geometrical characterization of inkjet-printed conductive lines of nanosilver suspensions on a polymer substrate

Kang BJ and Oh JH

Thin Solid Films, 518(10), 2890-2896 (2010)

Highly conductive nano-silver circuits by inkjet printing

Zhu D and Wu M

Journal of Electronic Materials, 47(9), 5133-5147 (2018)

商品

Small molecular weight organic semiconductors are promising for flexible transistor applications in next-gen soft electronics.

Professors Tokito and Takeda share design principles and optimization protocols for organic electronic devices, focusing on flexibility and low cost.

我们的科学家团队拥有各种研究领域经验,包括生命科学、材料科学、化学合成、色谱、分析及许多其他领域.

联系客户支持