SyTracks Carbon Monoxide Generator FAQs

General Information

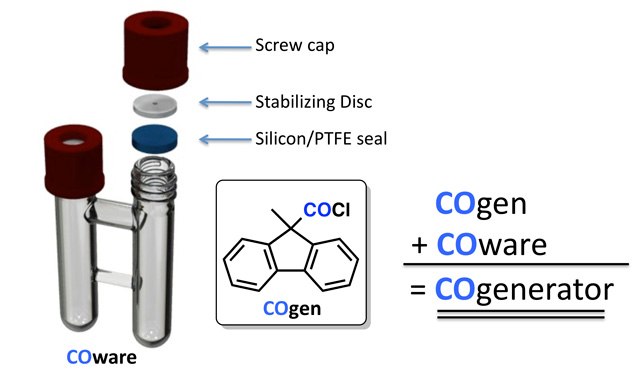

Figure 1.The SyTracks Carbon Monoxide Generator

What is COgen?

What is COware?

What is the SyTracks COgenerator system?

COgen combined with COware affords the SyTracks COgenerator system, a safe system for the efficient handling and application of CO at 14–46 psi (1–3 bars) for any carbonylation purpose.

What are the benefits of applying the COgenerator system compared to solutions solving the same problem?

When the SyTracks COgenerator is used, the direct handling of CO is avoided. This provides a safe and simple method of performing carbonylation chemistry.

- The need for hazardous pressurized CO canisters is avoided.

- The COgenerator provides a more reliable and robust CO delivery than a balloon of CO.

- Expensive and cumbersome autoclave systems are avoided, at the same time providing the benefit of operating at slightly elevated pressures.

- Cost-effective isotope labeling with 13CO.

Can CO from COgen be compared to CO from a pressurized canister?

CO produced from COgen corresponds directly to CO being delivered from a pressurized canister. When the same solvent is employed in the COgenerator as in the reaction chamber, no cross-contamination is likely to occur.

Is a glovebox required?

Setup in a glovebox is not required due to the unique design of COware. The combination of the PTFE coated silicone seal with the COware stabilizing discs provides a pierceable and resealable closure system, which allows for purging with an inert gas if needed before heating the reaction.

Is the COgenerator air-sensitive?

No, the COgenerator is tolerant to ambient air.

Who would use the COgenerator?

As COgen and COware presents a standard reaction flask solution to reactions with gases and fits into any fumehood, it is highly suitable for any research by medicinal and/or developmental chemist within academia as well as industry.

What other reagents are required to release CO from COgen?

- Almost any given palladium(0) or palladium (II) source. CO will be released at catalyst loadings down to 0.1 mol %.

- [(t-Bu)3PH]BF4 (Product No. 578940)

- Cy2NME (Product No. 294942), alternatively; Et3N or i-Pr2NEt.

- Any aprotic solvent such as toluene, dioxane, DME, THF, CPME, DMF, NMP, paraffin, isopropyl acetate, etc.

What if I need to run my reaction in a protic solvent?

A high-boiling aprotic solvent is chosen for CO generation.

What are the typical experimental conditions for the COgenerator?

For 0.5 mmol substrate in the reaction chamber, 0.75 mmol (1.5 equivalents) of COgen is typically applied. To release CO from 0.75 mmol of COgen, 0.0075 mmol Pd(dba)2 (1 mol %), 0.0075 mmol [(t-Bu)3PH]BF4 (1 mol %), 1.125 mmol Cy2NMe, and 3 mL of toluene are used.

How fast does COgen release CO?

Using typical conditions: (toluene, [(t-Bu)3PH]BF4, Pd(dba)2, 80 oC, Cy2NMe) CO is completely released within 10 minutes.

What is the maximum operating pressure?

COware should not be operated above 60 psi.

Is there a maximum loading of COgen in COware?

The maximum loading of COgen is related to the maximum operating pressure. For COware volume of 20 mL and disregarding heating above ambient temperature, gaseous byproducts, and solvent vapor pressure: With a combined volume of reagents, starting materials, and solvents in the two chambers of 6 mL, a headspace volume of 14 mL results. Loading 1.9 mmol of COgen gives 46 mL CO gas and thus results in a combined internal pressure of 60 psi (60 mL gas in a 14 mL volume).

Related Products

如要继续阅读,请登录或创建帐户。

暂无帐户?