KitAlysis™ High-Throughput Screening Platform

In the high-pressure environment of discovery chemistry, time is everything. While general catalytic methods exist, substrate dependency makes it difficult to predict optimal conditions in practice. A thoughtful screening process is the best way to cover a large amount of chemical space quickly while using small amounts of often precious intermediates.

KitAlysis High-Throughput Screening Kits provide the optimal solution to quickly and efficiently identify or optimize suitable catalytic reaction conditions.

Features include:

- Microscale format requires only ~100 mg total of each substrate to run 24 unique chemical reactions (3–4 mg per reaction)

- Reaction array (catalysts, solvents, bases, and temperature) is designed and validated by practicing medicinal/process chemists in some of the largest pharma companies in the world

- All components are included. End-user supplies only substrate and commonly used lab essentials (pipettes and syringes)

- KitAlysis Labware eliminates the need to set up reactions in a glove box

KitAlysis technology showcases the most widely used catalytic methods of synthetic chemists in both academia and industry, translated into an off-the-shelf screening system. Now, any bench chemist can rapidly run 24 unique microscale reactions in parallel with conditions tailored to ensure the best possible chance of success.

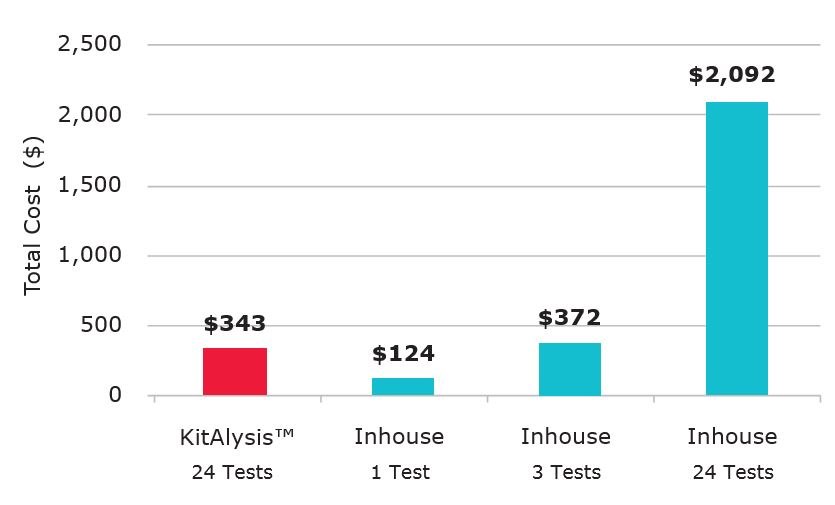

Head-to-head Comparison

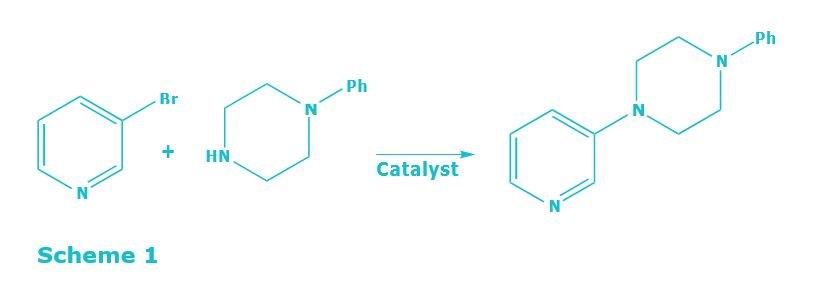

Head-to-head comparison of running test reaction (Scheme 1) under standard glove box conditions and using the KitAlysis™ Benchtop Inertion Box.

- Minimal typical cost of purchasing new catalyst.

- Average cost of the 12 catalyst in the kit based upon the smallest SKU size available, excludes anhydrous solvents and bases.

- Salary cost based on chemist salary http://cen.acs.org/articles/93/ i44/ American-Chemical-Societys-Members-Earn . Average time to plan, set-up, and analyze (single reaction = 1 hour, 24 reactions with KitAlysis = 2 hours)

Materials

如要继续阅读,请登录或创建帐户。

暂无帐户?