Signal Peptide Optimization: Effect On Recombinant Monoclonal IgG Productivity, Product Quality And Antigen-Binding Affinity

Abstract

A signal peptide is a 5-30 amino acid (aa) peptide present at the N-terminus of secretory proteins. Signal peptides are known to have a strong impact on both the efficiency of protein secretion and correct processing at the N-terminus. N-terminal heterogeneity can have an impact on both the product quality and bioactivity of the bio-therapeutic product.

In this study, we evaluated two signal peptide sequences for a model recombinant humanized IgG. Productivity was evaluated at the transient transfection and stable (bulk and minipool) stage using FACS analysis. N-terminal cleavage was evaluated using peptide mapping and intact mass analysis. N-terminal heterogeneity was observed with one of the signal peptides resulting in a major species with D mass 159 added to the N-termini of the Light Chain. No effect on either the product quality or the antigen binding affinity of the purified product was seen. Site directed mutagenesis was successfully used to re-engineer the signal peptide to prevent this mis-cleavage. However, this resulted in a decrease in the productivity of the recombinant IgG, without affecting the product quality or bioactivity. The results underscore the importance of evaluating more signal peptide designs with a balanced optimization strategy to ensure correct N-terminal cleavage and high productivity.

Background and Methods

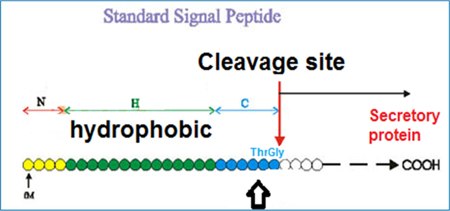

Figure 1.Structure of a signal peptide.

Signal peptides do not consist of a strict consensus sequence but have a three-region design consisting of a positively charged N-terminal region (n-region), a hydrophobic central region (h-region) and a neutral, polar C-terminal region (c-region).

Materials and Methods

Cell Culture and Fed Batch Assay

CHOZN® GS -/- host cell lines were transfected and single cell clones generated expressing the model humanized monoclonal antibody. Two different vector backbones: CLE 305 and CLE 306 were evaluated. Fed batch assays were carried out in duplicate 50-ml TPP™ bioreactor tubes and replenished with glucose and glutamine or glucose alone on days 4 and 7. Cultures were maintained in Ex-CELL® CHO CD Fusion (14365C).

Intact Protein Accurate Mass Spectrometry

% Relative of total glycoform distribution of recombinant IgG using intact mass to access glycoforms was determined using a SEC-MS (Waters Acquity UPLC®/Q-TOF Premier™) method.

Surface Antigen Staining of Secreted IgG and Analysis by FACS

Transient or stably transfected cells were stained using a PE conjugated F(ab’)2 fragment Donkey Anti-human IgG (Jackson ImmunoResearch Laboratories Inc # 709-116-149). Washed two times with PBS and analyzed on FACS.

Site Directed Mutagenesis

Primers including 6 base pair deletion corresponding to the two amino acids at the C-terminus of the Signal Peptide (Threonine and Glycine) on the Light Chain were designed and synthesized. Site-Directed Mutagenesis of CLE 306 vector was performed using the QuikChange II XL Kit, (Agilent, Cat#200521-5) as per manufacturer’s protocol. The new vector was called CLE 323. CLE 306 was also recloned germ line signal peptide on the Light Chain. The new vector was called CLE 320.

Results

Expression Confirmed at Transient and Stable Pools

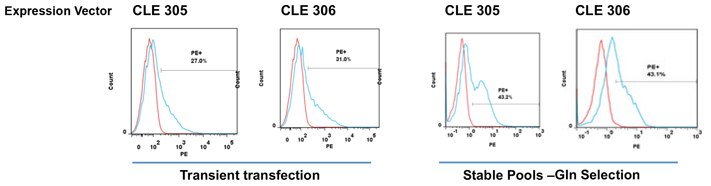

Figure 2.Surface antigen staining of the secreted IgG using a PE conjugated antibody followed by FACS analysis.

Expression of secreted antibody was confirmed at the transient stage and in the stable pools generated under –Glutamine selection.

N-terminal heterogeneity of Light Chain

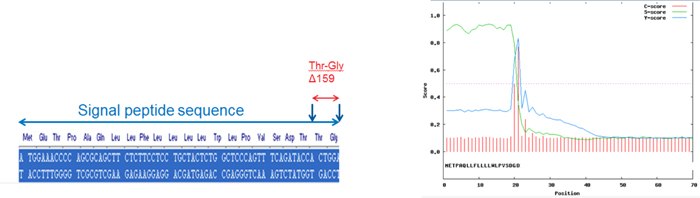

Figure 3.Deconvoluted MS spectra of Code H HC and LC.

HC peaks are in accordance to the proposed HC sequence with C-terminal Lys truncated. The major peaks are (G0F, -K), (G1F, -K) and (G2F, -K).

The observed LC shows two peaks one at the expected size and a second major peak with + Δmass of 159 Da. This correlates with the mass of “ThrGly-” C-terminal amino acids of the signal sequence. Peptide mapping results confirmed correct processing of the N-terminus of the HC, while the LC had a peptide with the expected mass + 159.

Engineering of Signal Peptide for Correct Processing

Figure 4.Site directed mutagenesis was used to delete two C-terminal aa from the Signal Peptide sequence on the LC. Signal P and SIGCleave softwares predicted correct processing of the engineered signal peptide.

Correct Processing in Germ line and Engineered Signal Peptide

Expression Vector

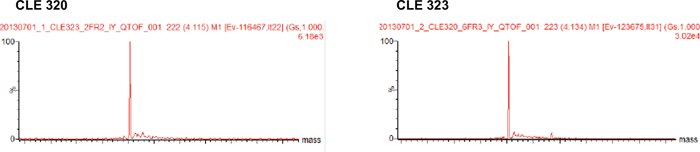

Figure 5.Deconvoluted MS spectra of Code H LC.

Left figure using the germline Signal Peptide sequence on LC and on the right using the engineered version 2 signal peptide.

Product Quality and Antigen Binding Affinitly

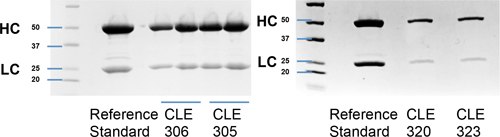

Figure 6.SDS-PAGE denaturing gel of purified recombinant IgG.

Left figure using the germline Signal Peptide sequence on LC and on the right using the engineered version 2 signal peptide.

Effect on Recombinant IgG Productivity

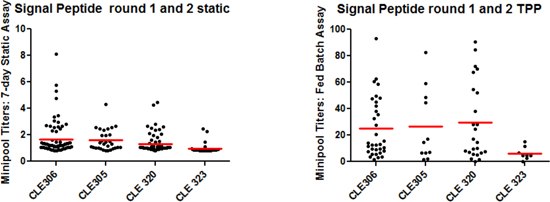

Figure 7.Minipool static and fed batch shake culture titers

Conclusions

- Signal peptide on the Light Chain of CLE 306 and CLE 305 resulted in both transient and stable expression of the model IgG.

- This version resulted in miscleavage of the signal peptide sequence resulting in

- A major peak with + Δ mass 159

- This mass corresponds to the mass of two amino acids Threonine + Glycine preceding the cleavage site

- No effect on product quality was observed - Germ line signal peptide on the Light Chain (CLE 320) resulted in correct signal peptide processing

- Re-engineering of the signal peptide to remove the two amino acids Threonine + Glycine by site directed mutagenesis also resulted in correct signal peptide processing

- No difference in product quality or antigen binding affinity was seen

- Productivity was decreased in the re-engineered signal peptide, with decreased expression at the minipool static and and

Fed batch cultures - The results underscore the importance of evaluating more signal peptide designs with a balanced optimization strategy to ensure correct N-terminal cleavage and high productivity.

Acknowledgements

Internal Analytical R&D:

Isil Yasa, Kevin Ray

CHOZN® Platform Team

Materials

如要继续阅读,请登录或创建帐户。

暂无帐户?