Hydroxymethylfurfural (HMF) Analysis of Beer by HPLC-UV using a 4.6 mm ID Monolithic Silica Column

Hydroxymethylfurfural (HMF)

(5-(hydroxymethyl)furfural)

Section Overview

Introduction

Hydroxymethylfurfural (HMF) is generated by thermal decomposition of carbohydrates or sugars. It can be detected in many heat-treated food and beverage samples. In the latter, low levels of HMF indicate its freshness and natural finish, while long-term storage or exposition to heat leads to high HMF content, caused by fructose decomposition.

HMF is suspected to have negative health effects on animals and humans1 hence more attention is given to this by official institutions like the European Union2, where e.g. limit values for honey are defined.3

This application focusses on the analysis of HMF in the different beer samples, smoke beer, wheat beer dark, and dark beer by HPLC with UV detection using a matrix tolerant monolithic silica column, the Chromolith® HighResolution RP-18 endcapped.

Figure 1.HMF standard working solution 10 mg/L (Peak 2: HMF).

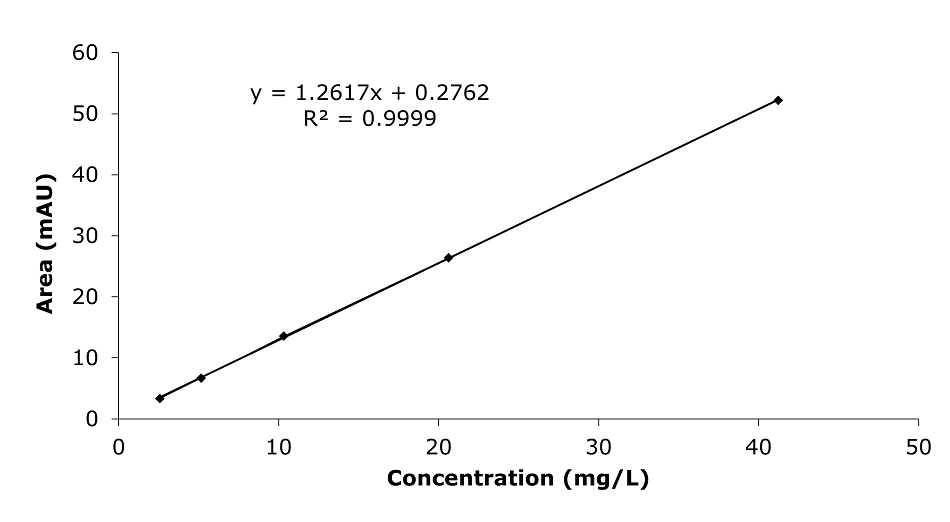

Calibration

An external calibration curve was established using 7 concentrations (Table 3 & Figure 2)

Figure 2.Calibration curve of HMF standards.

Sample Measurements

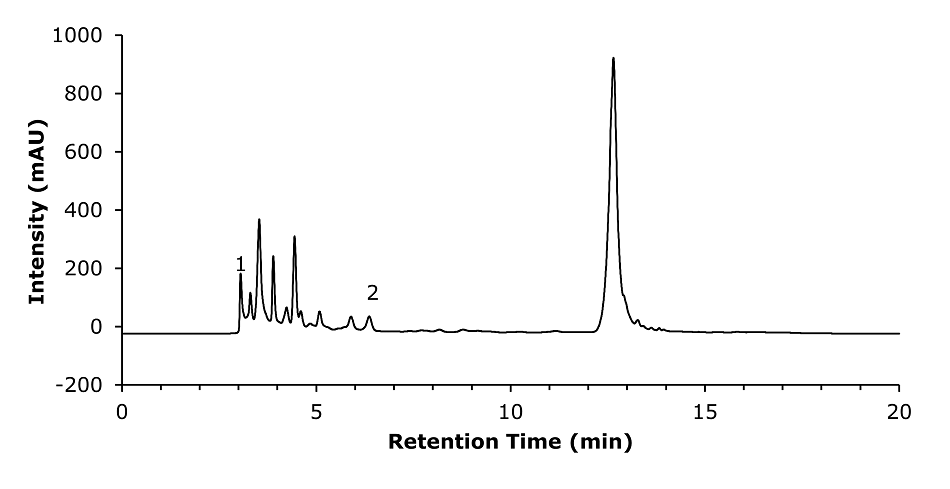

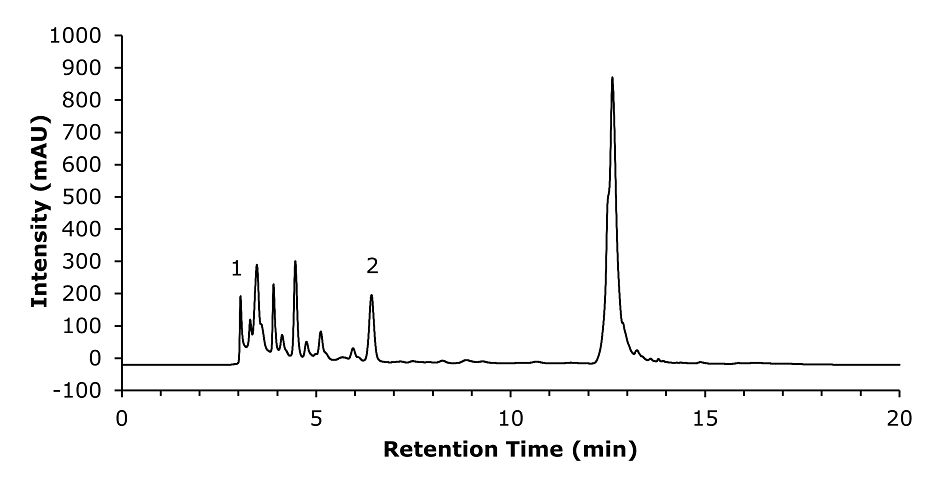

As examples for beer samples, the results for the smoke beer unspiked and spiked (20 mg/L) are presented below (Figures 3 & 4, Tables 4 & 5). Reproducibility was determined by injecting each beer sample 5x (Table 6). In Table 7 an overview of the measure unspiked and spiked is displayed.

Figure 3.Injection of a smoke beer sample (Peak 2: HMF).

Figure 4.Injection of a spiked (20 mg/L HMF) smoke beer sample (Peak 2: HMF).

Conclusion

The developed simple HPLC-UV method allows for a 5-HMF test in three different beer samples on a Chromolith® HighResolution RP-18e 100x4.6 mm column with an LOD of 0.6 mg/L and LOQ of 1.8 mg/L. The recoveries for spiked beer samples were between 88.9% and 94%.

The bimodal pore structure of the monolithic silica Chromolith® HighResolution column provided the matrix tolerance that allowed us to reduce the sample preparation to a minimum (just degassing). By this, the workflow could be kept short, which otherwise typically requires more elaborate sample preparation steps like SPE to, e.g. avoid column clogging.

Another way of HMF determination can be performed by a rapid photometric test that can be found in our Manual on Analysis Methods for the Brewery Industry. This covers a range of other parameters for the brewery industry and is complemented by e.g. our application note on Sulfur Dioxide in Beer Photometric Determination with Ellmann’s Reagent.

More applications on Food & Beverage Testing

REFERENCES

如要继续阅读,请登录或创建帐户。

暂无帐户?