Viral Inactivation

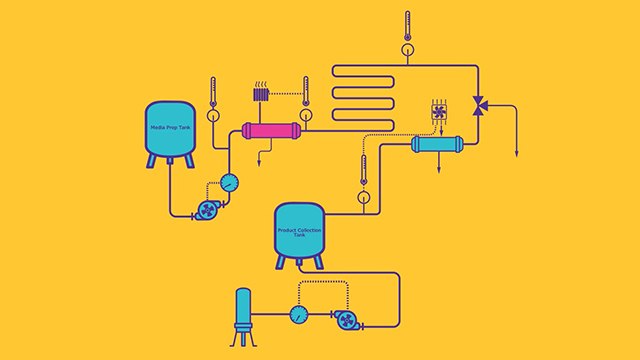

Viral safety is a critical component of assuring the safety profile of drug products for patients. In contrast to chromatographic separation or virus filtration which remove viruses, viral inactivation steps use chemicals or low pH to reduce the levels of infectious enveloped viruses.

While the approach to viral inactivation is highly dependent on the process and molecule, the underlying needs are the same: high quality chemicals, free of viral contaminants that are suitable for biologics manufacturing.

Our differentiated chemical solutions offer the quality and safety profile you need for biologics manufacturing.

Explore our offering and services for:

Products

Solvent/detergent treatment

Solvent/detergent treatments disrupt the lipid membrane of enveloped viruses, leading to viral inactivation. This virus inactivation treatment is typically performed in addition to other viral clearance steps and is particularly useful where alternative viral inactivation methods, such as low pH inactivation, are not feasible.

Triton™ X-100 detergent has long been used for viral inactivation in biologics processing. However, owing to restrictions in the European Union due to its listing under REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), we have developed our Deviron® detergent portfolio: Deviron® C16 Emprove® Evolve detergent and Deviron® 13-S9 Emprove® Expert detergent. These sustainable detergent solutions for the biopharma industry have excellent viral inactivation performance and are easily removed during processing.

Notably, the Deviron® detergents are part of the Emprove® Program.

Explore the benefits of Deviron® sustainable detergents.

Low pH Treatment

Low pH treatment is typically used for inactivation of enveloped viruses in monoclonal antibody (mAb) manufacturing, however for pH sensitive molecules viral inactivation with detergent may be preferred.

Successful viral inactivation in bioprocessing relies on high-quality acids and buffers which feature low bioburden and endotoxin levels and are manufactured or purified under good manufacturing practices (GMP) for consistent high purity and performance.

Explore our range of high-quality acids and buffers.

Speeding you through the regulatory maze

As part of our industry-leading Emprove® Chemicals portfolio, all materials for virus inactivation are supported with comprehensive, up-to-date documentation to help you navigate regulatory challenges, manage risks, and improve processes.

All reagents are integrated with our Emprove® Program to simplify your raw material qualification and documentation process. Our Emprove® Expert portfolio is designed for higher-risk applications requiring low bioburden and endotoxin levels.

Learn more about our Emprove® Program and request a demo dossier here.

Viral Clearance Testing Services

Viral clearance studies demonstrate the capability of downstream processing steps to remove or inactivate endogenous and adventitious viruses and are a crucial component of regulatory submissions.

Our team of regulatory, downstream processing, and virology experts offer decades of experience in designing and executing clearance studies, that align with regulatory expectations. Our Bioreliance® Viral Clearance Services can be tailored to meet your specific needs enabling you to minimize risk and ensure the safety of your products for patients.

Learn more about our BioReliance® Viral Clearance Services.

Related Resources

- Application Note: Deviron® Detergents for Viral Inactivation

Deviron® C16 and Deviron® 13-S9 Detergents for Solvent/Detergent Viral Inactivation of Plasma in Mobius® Single-Use Containers

- Brochure: The Deviron® Detergent Portfolio

Greener Alternatives to Triton™ X-100 for Biopharmaceutical Applications.

- Flyer: Deviron® 13-S9 Detergent, EMPROVE® Expert

Aligning with two principles of Green Chemistry: Designing safer chemicals and Design for degradation.

To continue reading please sign in or create an account.

Don't Have An Account?