1.10317

Fractogel® EMD BioSEC (S)

Synonym(s):

Fractogel® EMD BioSEC (S)

Select a Size

Select a Size

About This Item

Recommended Products

ligand

(Modified pore structure)

Quality Level

description

for size exclusion chromatography (SEC), suspension in 20% ethanol and 150 mM NaCl (20-40 µm)

product line

Fractogel®

parameter

100 cm/hr max. flow rate

8 bar pressure

matrix active group

Methacrylate

mean particle size

20-40 μm

transition temp

flash point 35 °C (calculated)

density

1.43 g/cm3 at 20 °C

application(s)

viral therapy

Related Categories

1 of 4

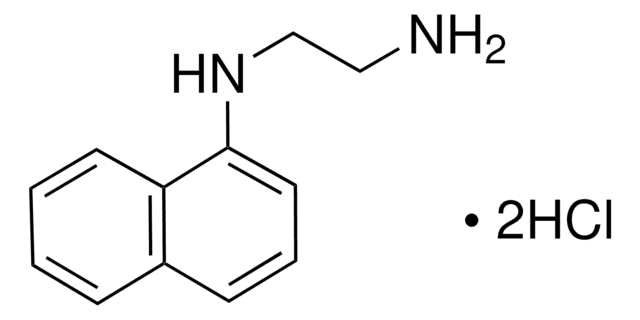

This Item | D163708 | 274992 | N9125 |

|---|---|---|---|

| Quality Level 200 | Quality Level 200 | Quality Level 200 | Quality Level 200 |

| mp 86-88 °C (lit.) | mp 112-115 °C | mp 130-133 °C (lit.) | mp 194-198 °C (dec.) (lit.) |

General description

Features and Benefits

- Effectively remove dimer and high molecular weight aggregates and complete an efficient polishing of blood plasma factors

- Determine apparent molecular weights of proteins

- Move predictably and efficiently from bench scale to manufacturing scale processing

- Create a robust, consistent, and transferable process

Packaging

Analysis Note

Microscopic evaluation: Uniform sphericalparticles, noagglomerates, nofines

Extractable matter (water): ≤ 0.03 %

Cerium: ≤ 1 µg/g

Pressure drop(column: ID=1.6 cm, L=10 cm at 5 ml/min): ≤ 5.0 bar

Particle size (d10): 20 - 28 µm

Particle size (d50): 24 - 34 µm

Particle size (d90): 28 - 38 µm

Colony forming units (TAMC + TYMC): ≤ 100 CFU/ml

Endotoxins: ≤ 1.00 EU/ml

Function test (b:a): ≤ 0.7

function test (c:d): ≤ 0.05

Functional Test: Separation of bovine serum albumin, ovalbumin and cytochrom C

Legal Information

Signal Word

Warning

Hazard Statements

Precautionary Statements

Hazard Classifications

Flam. Liq. 3

Storage Class Code

3 - Flammable liquids

WGK

WGK 3

Flash Point(F)

95.0 °F

Flash Point(C)

35 °C

What is the Emprove® Program?

The Emprove® Program is a system providing comprehensive and thorough documentation of our filters and single-use components, pharma raw materials, and starting materials. Four document types are included with an Emprove® Program subscription:

Free of charge - Sign in to download

Free of charge - Sign in to download

Available by subscription or for a fee

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Influenza vaccines are commonly made using egg-based and cell-based manufacturing strategies. Find step-by-step information on the manufacturing process for each method.

A custom-designed cost model is used to explore the economics of vaccine manufacturing across several different modalities including mRNA. The model enables greater process understanding, simulates bottlenecks, and helps to optimize production efficiency.

Learn more one the attenuated viral vaccines manufacturing process: cell culture, clarification, nuclease treatment, chromatography, and sterile filtration.

This technical article breaks down the steps of upstream and downstream bioprocessing and formulation of virus-like particle vaccines.

Related Content

This technical article breaks down the adenovirus vaccine manufacturing process and provides a case study on developing an accelerated and cost-effective single-use adenoviral vector vaccine.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service