From Research to Application: The Role of Advanced Electrolytes in Sodium-Ion Batteries

Introduction

Sodium-ion batteries (SIBs) are emerging as a compelling alternative to lithium-ion batteries (LIBs), primarily due to the abundant availability and low cost of sodium resources. As the demand for energy storage solutions continues to grow,1 SIBs offer a promising pathway to meet energy storage needs while addressing concerns related to lithium supply and environmental impacts.2 With advancements in materials science, SIB technology is rapidly evolving, particularly through the development of high-performance electrolytes that enhance the efficiency and longevity of these systems. In this article, we will discuss the fundamental science of electrolytes and then dive into the advantages and tradeoffs of key materials.

Sodium-Ion Battery Electrolyte

Electrolytes play a pivotal role in the performance of sodium-ion batteries (SIBs). They serve as the medium through which sodium ions travel between the cathode and anode during the charge and discharge cycles. A sodium-ion battery electrolyte is composed of a sodium salt, a solvent or solvent mixture, and additives. The choice of electrolyte significantly impacts material properties such as ionic conductivity, electrochemical stability window, and formation of a solid-electrolyte interphase (SEI), which in turn affects critical performance metrics like cyclability, performance during fast-charging, operable temperature window, and energy density.3

Ionic Conductivity of Sodium Ion Battery Electrolyte

Figure 1.Ionic conductivity of sodium-ion electrolytes, showing that ionic conductivity is related to salt concentration.

Ionic conductivity is a measure of how easily ions can move through the electrolyte. High ionic conductivity is essential for efficient ion transport, with typical values around 3-20 mS/cm.4 Allowing more ions to move between electrodes in a set period enables faster charging and discharging rates. Conversely, poor ionic conductivity can degrade many battery parameters, such as increasing electrochemical polarization and higher internal resistance.

There are a few critical factors that influence ionic conductivity:

Figure 2.Viscosity, melting point, and dielectric constants of common battery solvents used in sodium-ion electrolytes.

Figure 3.Electrochemical window of 1.0 M sodium-ion electrolytes taken from cyclic voltammograms.

The electrochemical stability window of an electrolyte is the voltage range within which the electrolyte can operate without decomposing.8 A wide stability window is preferred because it supports higher operating voltages, thereby increasing the battery's energy density. Generally, NaPF6-based and NaClO4-based electrolytes have stability windows of at least 0-4 V vs. Na+/Na, making them useful for benchmarking cathode and anode materials.9

However, the stability window is not solely a property of the electrolyte; it also depends on the materials used for the current collectors and electrodes. For instance, NaTFSI and NaFSI in carbonate solvents tend to corrode aluminum current collectors at voltages beyond 3.7 V vs. Na+/Na, thus limiting their stability window.

SEI Formation

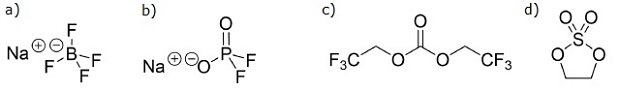

A stable solid-electrolyte interphase (SEI) is crucial for the longevity and safety of sodium-ion batteries (SIBs). The protective layer forms on the anode, preventing further electrolyte decomposition while allowing sodium ions to pass through.10 This stable SEI layer formation significantly impacts battery performance by retaining energy density over many cycles and facilitating fast charging. Additives play a critical role in enhancing the SEI. Sodium salt additives like NaBF4, NaDFOB, and NaPO2F2 are effective at forming a fluorine-rich SEI, which improves battery performance. Similarly, liquid additives such as FEC, DFDEC, and DTD oxidize on the anode to create SEI films rich in fluorine or sulfur moieties, facilitating better sodium-ion conduction.11,12

Sodium Perchlorate (NaClO4)

(931950)

- Sodium Perchlorate (NaClO4): NaClO4-based liquid electrolytes are commonly used in SIB research due to their high ionic conductivity and wide electrochemical stability window. These properties make them ideal for fundamental studies of high-voltage oxide and polyanionic cathode materials. However, sodium perchlorate poses significant safety risks for industrial adoption and commercialization. It can explosively decompose at moderately high temperatures (~130°C) and is prone to explosion in its dry state when subjected to friction or shock.13

Sodium Hexafluorophosphate (NaPF6)

(940135)

- Sodium Hexafluorophosphate (NaPF6): NaPF6-based liquid electrolytes are highly attractive for industrial and commercial applications because they do not carry the same explosion risk as sodium perchlorate. Common commercial formulations include 1.0 M NaPF6 in PC, EC/DMC 1:1, and EC/DMC/EMC 1:1:1. These electrolytes offer high ionic conductivity (>5 mS/cm) and do not corrode aluminum foil. They also have wide electrochemical stability windows of 0-4 V vs. Na+/Na.14 While NaPF6-based electrolytes are compatible with most electrode materials, they generally require additives like FEC, NaDFOB, NaBF4, and NaPO2F2 to efficiently plate and strip sodium-metal anodes. The main drawbacks of NaPF6-based electrolytes are their thermal stability and sensitivity to moisture. Therefore, battery-grade NaPF6 and its electrolytes must be kept rigorously dry, 15 and additives may need to be developed to facilitate their use at higher operating temperatures.

Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI) (936049)

- Sodium Bis(trifluoromethanesulfonyl)imide (NaTFSI): NaTFSI-based electrolytes offer better thermal stability and are less sensitive to moisture compared to NaPF6-based electrolytes.16 They are considered safer to handle because they do not hydrolyze to form HF when exposed to trace moisture. Two excellent formulations are 1.0 M NaTFSI in EC/DMC 1:1 and 1.0 M NaTFSI in EC/DMC/EMC 1:1:1. These electrolytes achieve similarly high ionic conductivities (>5 mS/cm) as NaPF6-based or NaClO4-based electrolytes and are compatible with many common electrode materials, including hard carbon, layered oxides, sodium vanadium phosphate, and polyanionic cathode materials. The main drawback of NaTFSI-based electrolytes is their tendency to corrode aluminum foil at potentials around 3.7 V vs. Na+/Na, which limits their use in very high-voltage batteries. This corrosion can be mitigated by adding 0.05 M NaPF6 to the formulation, which helps passivate the aluminum current collector. This dual-salt approach is a promising avenue for NaTFSI-electrolyte design.16

Sodium Bis(Fluorosulfonyl)imide (NaFSI) (939900)

- Sodium Bis(Fluorosulfonyl)imide (NaFSI): NaFSI-based electrolytes behave similarly to NaTFSI-based electrolytes. They are also considered safer to handle and can achieve high ionic conductivities. However, like NaTFSI, NaFSI-based electrolytes tend to corrode aluminum current collectors and do not offer the same improvements in thermal stability as NaTFSI.17

Sodium-triflate (NaTfO)

(936030)

- Sodium Triflate (NaTfO): Sodium-triflate-based electrolytes are emerging as a safer and more stable alternative in the realm of sodium-ion batteries. The triflate anion is stable and does not hydrolyze or form hydrofluoric acid, making NaOTf electrolytes safer to handle than NaPF6-based ones. Additionally, NaOTf offers better thermal stability and does not corrode aluminum current collectors, unlike NaTFSI and NaFSI. The main challenge with NaOTf electrolytes is their ionic conductivity. NaOTf tends to form ion pairs in solution, leading to strong solvation that impedes ionic conductivity, especially in carbonate solvents. Therefore, selecting the appropriate solvent is more challenging for sodium-triflate-based electrolytes. One effective formulation is 1.0 M NaOTf in diglyme, which achieves an ionic conductivity of ~4 mS/cm at room temperature.18 This formulation is gaining attention for sodium metal batteries due to its efficient sodium plating and stripping capabilities.

Sodium Difluoro(oxalato)borate (NaDFOB)

(933953)

- Sodium Difluoro(oxalato)borate (NaDFOB): NaDFOB-based electrolytes are highly promising but less studied. With surprising solubility (>1.0 M in carbonates), NaDFOB can serve as the primary electrolytic salt in a sodium-ion electrolyte and achieve high ionic conductivity (>5 mS/cm in EC/DMC, EC/DEC, and EC/PC). It exhibits excellent electrochemical stability from 0-5.5V vs. Na+/Na, surpassing even NaClO4. Additionally, NaDFOB-based electrolytes and electrolytes using NaDFOB as an additive perform well with sodium metal anodes. Researchers have proposed that NaDFOB forms a protective SEI layer on sodium metal anodes that is made of sodium borates and sodium fluorides and prevents dendrite formation. Moreover, NaDFOB is stable and does not produce any toxic or hazardous substances upon contact with air and water. These observations make NaDFOB-based electrolytes a promising direction for SIB electrolytes.19

Conclusion

Sodium-ion battery research is on the brink of significant technological breakthroughs. The development of advanced electrolytes, including innovative electrolytic salts, additives, and formulated electrolytes, is crucial for enhancing the efficiency, safety, and longevity of these batteries. By focusing on critical aspects of electrolyte performance—such as ionic conductivity, electrochemical stability, and SEI formation—researchers can drive forward the capabilities of sodium-ion batteries and contribute to a more sustainable and energy-efficient future.

Discover the webinar, Shaping the Future of Sodium-Ion Batteries: From Accelerated Solid-State Electrolyte Discovery to Hard Carbon Design and explore the future of energy storage with sodium-ion batteries.

Related Products

References

如要继续阅读,请登录或创建帐户。

暂无帐户?