Bioreactor Production

Stainless steel installations are often cost-prohibitive and time-consuming. In contrast, adoption of single-use or hybrid systems represents a faster, more flexible, and less capital-intensive route. When selecting a single-use bioreactor platform, key considerations include scalability and quality control:

- To successfully implement a large-scale single-use bioreactor platform, equivalent performance or scalability with smaller sized bioreactors across the platform must be demonstrated. Characterization of key engineering parameters, including power input per volume, mixing time, oxygen transfer capabilities, and temperature mapping across all scales are required.

- For single-use products and systems to meet high quality standards, there must be a mature quality control system in place. The system needs to manage the entire life-cycle, from component selection, testing and qualification, to assembly manufacturing, in-process testing, and final product release.

Featured Categories

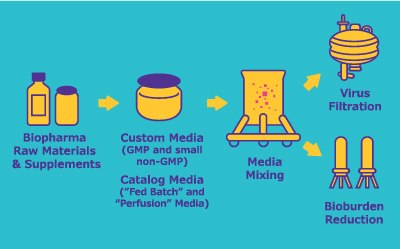

Our off-the-shelf and customizable bioprocessing cell culture media (CCM) products enhance productivity in upstream mAb, vaccine, gene/cell therapy processes.

The Mobius® Bioreactor family offers single-use bioreactors for cell culturing from early development to commercial production, supporting various scales.

Explore Mobius<sup>®</sup> single-use mixing solutions for pharmaceutical ingredient blending and process solution preparation.

Managing Process Scale-up and Tech Transfer of an Upstream Suite

Converting from pilot to process scale and transferring technology requires precise and seamless organization, communication, and documentation. A well-developed technology transfer package:

- Provides a clear understanding of the process and technologies

- Determines the appropriate path to achieve goals of the project

- Aligns with the pharmaceutical quality management system as outlined in ICH Q10

Visit our document search for data sheets, certificates and technical documentation.

Related Articles

- Viral safety in bioprocessing relies on a framework of (1) preventing contamination, (2) detecting contamination, and (3) removing or inactivating viral contaminants.

- Multivariate data analysis (MVDA) makes possible a proactive, real-time approach to monitoring, controlling, and predicting quality and productivity in biomanufacturing. The use of proven software with guided PCA and PLS model creation means you don’t need to be a data scientist to explore and analyze your data.

- Key aspects of single-use assembly qualification including quality by design (QbD), quality risk management (QRM) and operator handling and training.

- Before adoption of single-use technologies in biomanufacturing, manufacturers must assess the risk to the drug product from potential leachables. This article highlights a general approach based on the United States Pharmacopeia (USP).

- Discover how low-impurity iron sources improve reliability and performance in recombinant protein production with EX-CELL® Advanced medium.

- See All (15)

Related Protocols

- This article describes a purification process resulting in low nanoparticulate impurities sucrose, enabling more stable protein formulations.

- See All (1)

Find More Articles and Protocols

Related Product Resources

- Tech Brief: Mobius® Single-use Bioreactors: Platform Scalability

This brief discusses the characteristics and performance of Mobius® single-use bioreactors, emphasizing their scalability from 3 L to 2000 L for mammalian cell culture and recombinant protein production, and outlines critical engineering parameters for successful scale-up in biomanufacturing processes.

How Can We Help

In case of any questions, please submit a customer support request

or talk to our customer service team:

Email custserv@sial.com

or call +1 (800) 244-1173

Additional Support

- Chromatogram Search

Use the Chromatogram Search to identify unknown compounds in your sample.

- Calculators & Apps

Web Toolbox - science research tools and resources for analytical chemistry, life science, chemical synthesis and materials science.

- Customer Support Request

Customer support including help with orders, products, accounts, and website technical issues.

- FAQ

Explore our Frequently Asked Questions for answers to commonly asked questions about our products and services.

Workflow

Cell Line Development

Development begins by selecting single-cell clones that can produce the biologic of interest, then screening for clones that are stable, productive, and scalable

Media and Process Development

Achieving consistent cell culture performance requires careful screening, selection, and optimization of media formulations and feed

Monoclonal Antibody Manufacturing

Monoclonal antibody manufacturing is a highly templated approach used to produce mAb-based immunotherapies. Robust, scalable process solutions are required at every step to ensure high therapeutic concentration and process safety, while meeting speed-to-market and cost containment concerns.

To continue reading please sign in or create an account.

Don't Have An Account?