Polyethylene Glycol (PEG) Selection Guide

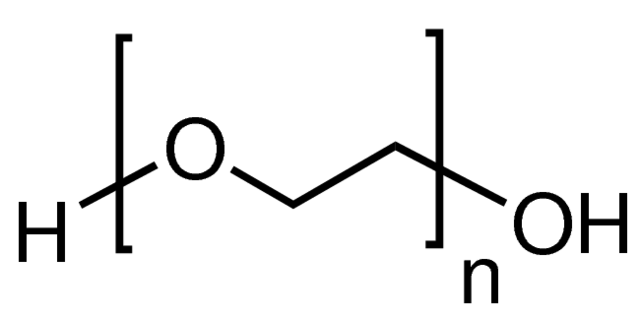

Poly(ethylene glycol) (PEG) structure

What is Polyethylene Glycol?

Poly(ethylene glycol) (PEG) is a synthetic, hydrophilic, biocompatible polymer with widespread use in biomedical and other applications. PEGs are synthesized using a ring-opening polymerization of ethylene oxide to produce a broad range of molecular weights and molecular weight distributions (polydispersity); however, discrete PEGs (dPEG® reagents) are synthesized with a single, specific molecular weight. PEGs can be synthesized in linear, branched, Y-shaped, or multi-arm geometries. PEGs can be activated by the replacement of the terminal hydroxyl end group with a variety of reactive functional end groups enabling crosslinking and conjugation chemistries.

Featured PEG Products

How is Polyethylene Glycol used?

PEGs are non-toxic, FDA-approved, generally nonimmunogenic, and are frequently used in many biomedical applications including bioconjugation,1 drug delivery,2,3 surface functionalization,4 and tissue engineering.5 Bioconjugation with PEG (also known as PEGylation) is the covalent conjugation of drug targets such as peptides, proteins, or oligonucleotides with PEG for the optimization of pharmacokinetic properties.6 In drug delivery, PEGs can be used as linkers for antibody-drug conjugates (ADCs)7 or as a surface coating on nanoparticles to improve systemic drug delivery.6 PEG hydrogels are water-swollen, three-dimensional, polymer networks resistant to protein adhesion and biodegradation.8 PEG hydrogels are produced by crosslinking reactive PEG end groups and are commonly used in tissue engineering and drug delivery.

Common functional groups and their corresponding reactive groups are listed in the table below.

References

如要继续阅读,请登录或创建帐户。

暂无帐户?