Inkjet Printing for Printed Electronics

Introduction

In the past decade, the family of digital printing technologies has evolved from being just a tool to visualize information into a generator of functionalities. The phrase ′printing beyond color′ aptly sums up this transformation. While this family of printing technologies is still widely used to fulfill visual requirements, its development in the generation of functionality, especially in the field of printed electronics, has resulted in an explosion of new ideas and fabrication approaches leading to lean manufacturing. The basic premise of digital printing, namely the positioning of a liquid (ink) droplet or solid (toner) particle of microscopic volume directly correlated with the presence of information at each pixel of the image or text to be produced, enables the economic deposition of expensive materials, functional or otherwise, only on desired locations on a substrate, that is, a selective deposition.

In this article, one of the most important digital fabrication techniques, inkjet printing, is presented in detail as it is one of the key enabling technologies of printed electronics. In addition to a discussion on the classification of inkjet printing technology, various relevant aspects with respect to materials (inks, substrates) as well as respective pre-processing and post-processing steps are discussed. Finally, a selection of application examples is provided, illustrating the various possibilities of inkjet-printed electronics.

Research and development focusing on functional materials and hightech printing equipments are ongoing, leading to new innovations on a quasi-daily basis.

Background

Conventional Printing

Printing technology is one of the foremost inventions that hastened the progress of humankind by reliable transmission, exchange and preservation of knowledge. Even though Gutenberg′s invention of the letterpress with movable lead type has been in existence for over half a millennium, it has been in the past century, since the evolution of photography as basis for graphic-arts reproduction and more importantly in the past few decades since the dawn of the potent combination of printing and computerized information technology, that the range of printing technologies evolved ramifyingly, leading to their widespread utilization.1

Offset, gravure, screen and flexographic are the major types of conventional printing technologies. They typically require a printing master or a printing plate for every type of information (texts, graphics and pictures) to be reproduced. Hence, an elaborate and at times cumbersome prepress process is required before these technologies can be implemented. Once the preprocessing is complete, these technologies, with the exception of flatbed screen printing, can be used for rapid and large-scale production.

Digital Printing

Unlike conventional printing technologies, digital printing works without a physical, pre-manufactured master printing plate and prints without a significant impact force onto the substrate or sublayer.2 The basic premise of digital printing is the accurate positioning of a liquid droplet or solid (toner) particle of a microscopically small volume directly correlated with the presence of information at each binary unit of the imagery to be reproduced. As a result, digital printing does not have the key disadvantages of conventional printing, viz. complex working steps, typically large financial and time investments to generate the masters and set up the process. Although digital printing can be assigned certain drawbacks especially with respect to average throughput when compared to high-end conventional printing technologies, its credit lies in the fact that it has elaborated a variety of techniques and process designs making printing accessible to a broader audience. This versatility and adaptivity explains the high integration potential of digital printing techniques into existing manufacturing lines of established industries (e.g., printed circuit board), the same way it had reached industrial print shops (for book-on-demand) or revolutionized the small office/home office sector with desktop printers. The characteristic feature of digital printing technologies can be broadly classified into two groups: (1) direct to substrate, which consists of printing technologies (e.g., inkjet printing and thermal transfer printing) that transfer information directly onto the printing medium, i.e., substrate, and (2) direct to plate, which consists of printing technologies (e.g., electrophotography and magnetography) that transfer the information onto a printing plate, which, in turn, transfers it onto the printing medium.2

The basic premise of digital printing, namely the presence or absence of information at each pixel of the image or text to be reproduced, enables the deposition of materials, functional or otherwise, only on desired locations on a substrate, yielding a selective and hence economic deposition.

Printed Electronics

Even though the terms printed electronics and organic electronics are sometimes used interchangeably, they need not necessarily refer to the same group of technologies. Nevertheless, they do share a lot of enabling technologies and methodologies. Strictly speaking, printed electronics refers to the application of printing techniques, both conventional and digital, to fabricate electronic structures, devices and circuits, no matter which functional materials (ink) and substrates are used. The only prerequisite is that the functional material must be processable from the liquid phase. In the same sense, organic electronics deals with the application of organic materials, e.g., conductive polymers in the fabrication of electronic structures, devices and circuits on rigid or flexible substrates. Consequently, flexible electronics highlights the bendable substrate made of plastic or paper. In any case, the progress of printed electronics has opened up new vistas, leading to a multitude of possibilities in conception, design, fabrication, packaging and application of electronic devices and circuits.

The additive nature of printing processes, the range of materials that can be formulated as inks, and the possibility to cater to various production scales, ranging from prototype to large-scale, are some of the key factors that enable the deployment of printing processes in electronics fabrication. While almost all printing technologies, especially the conventional ones, have been used at some point in printed electronics, screen printing and inkjet printing are dominant3. Figure 1 depicts the printing technologies that are of interest to printed electronics and their characteristics.

Figure 1.Printing technologies that are of interest for printed electronics and their significant characteristics.

It is worthwhile to note that, apart from inkjet printing, all the other technologies listed in Figure 1. are conventional in nature. In spite of that, the digital inkjet printing is considered a key enabling technology for printed electronics for reasons listed in the next section. The classification, specifics and requirements of inkjet technology are discussed in detail, along with application examples that illustrate the suitability of this kind of technology for printed electronics.

Inkjet Printing Technology

Inkjet printing technology produces droplets of the ink contained in the fluid channel, with diameters ranging from 10 to 150 μm,6 which approximately corresponds to the diameter of the nozzle. The volume of the droplets is in the picoliter range. This technology is considered suitable for printed electronics due to the following reasons:

- It is a non-contact process that selectively deposits a wide range of materials onto a wide range of substrates in a drop-by-drop manner.

- The shop floor space requirements, the initial investment as well as the commissioning time to get an inkjet printing setup running are lower than most other printing technologies.

- It is suitable for a wide range of production scales, from prototyping to large-scale industrial production.

- Ink consumption and material wastage are minimal.

- It is flexible with regard to its positioning within a process chain.

- It can produce patterned thin films - a key requirement for organic electronics. It should be mentioned however, that manufacturing of highly complex integrated circuits (ICs) has exclusively been performed by specialized techniques deviating from standard inkjet to meet the requirements for a high spatial resolution for ultra-short transistor channel lengths.7a

Finally, it is possible to add functionalities using inkjet printing on a substrate that already has electronic structures and devices, fabricated using any other technology. Its non-contact, mask-less and master-less nature, along with the freedom to position the printhead directly on top of any 3D coordinate of the substrate, enable this aspect.

Classification

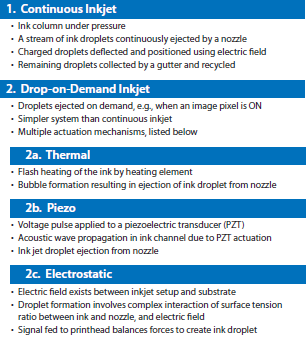

The inkjet technology is broadly classified into two categories, based on the mechanism of droplet generation.6 They are continuous inkjet (CIJ) and drop-on-demand inkjet (DOD). DOD printing is, in turn, classified into three types, namely thermal inkjet, piezo inkjet and electrostatic inkjet. Figure 2 depicts the overall classification of the inkjet printing technology, and the salient features of each individual technology.

Figure 2.Classification of the most common inkjet printing technologies.

In spite of the very high droplet generation frequencies (20-60 kHz), CIJ printing is not widely used in printed electronics as the recycling process after exposure to the environment might result in contamination of the ink. Moreover, CIJ is a potentially wasteful process, as a result of continuous generation of droplets irrespective of presence or absence of information at each pixel of the image or the text to be reproduced. However, CIJ has its advantage when it comes to work on substrates with a non-planar geometry.

As far as the DOD inkjet technologies are concerned, thermal inkjet and electrostatic inkjet lag far behind the piezo inkjet,9 mainly due to the following reasons:

- Thermal inkjet can lead to degradation of functional materials present in the ink due to the cyclic thermal loading. Piezo inkjet, on the other hand, is an isothermal process. Nontheless, thermal inkjet has successfully proven suitable for the manufacturing of light-emitting diodes based on inorganic quantum dots.7,8

- The range of ink solvents that could be used in piezo inkjet is much broader than thermal and electrostatic inkjet.

- The investment and running costs needed for an electrostatic inkjet is much higher than piezo inkjet. Moreover, this technique is still under development, and is not as mature as either piezo or thermal inkjet in its evolution.

Piezo Inkjet

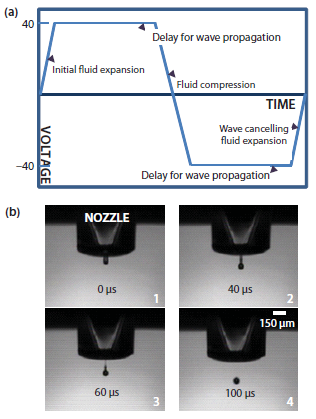

A piezo inkjet system, as its name indicates, consists of a piezoelectric transducer (PZT) that is actuated by a voltage pulse. This is called the inverse piezoelectric effect. In commercial printing systems, the frequency of the voltage pulse usually ranges from 1 kHz to 20 kHz. As a result of the piezo actuation, pressure (acoustic) waves are generated and propagated within the ink channel, and droplets are generated at acoustic frequencies.6

Figure 3a illustrates the commonly used bipolar waveform,10-12 along with a brief description of the significance of each segment of the waveform. This is just an example - many different types of waveforms can usually be applied to an inkjet printhead to create droplets. The profile and magnitude of the applied waveform depend on the nozzle dimensions, the rheology of the ink used, and the droplet size and velocity desired. Figure 3b shows a sequence of pictures depicting the formation of a droplet from a piezo inkjet nozzle.

Figure 3.a) Exemplary bipolar waveform for piezo actuation; b) Droplet formation sequence from the nozzle of a piezo inkjet printhead.

Requirements of Inkjet Printing

While the different types of inkjet printing technologies mentioned earlier more or less have similar requirements with respect to materials, pre-processing of the substrates and post-processing of the printed structures, this section focuses especially on the requirements of the piezo inkjet.

Substrate: As mentioned earlier, inkjet printing itself does not depend on the substrate. It is possible to use any type of substrate e.g., rigid, flexible, reinforced and non-reinforced. However, the interaction of the printed ink and the substrate plays a decisive role in determining the accuracy and robustness of the printed structure, and ink properties and substrate properties have to be well matched. As a result, the substrate surface is usually processed prior to printing in order to improve wetting, adhesion, etc. Plasma treatment and corona treatment are widely used for this purpose. For high-definition structures, substrate patterning, i.e., partitioning the substrate surface into hydrophilic and hydrophobic areas, is used.10-12

Inks: The inks used for printed electronics are either dispersed (pigmentlike) or dissolved (dye-like) in one or more solvents.13 The role of the solvents is to provide a vehicle by means of which functional materials could be carried through the printhead and ejected via the nozzle. In the context of printed electronics, a functional material fulfills an electronic/electrical functionality, e.g., conductivity, semiconductivity, resistivity and dielectricity. Many types of inks that fulfill these functionalities are commercially available.

The key characteristics of a piezo inkjet ink are: dynamic viscosity of less than 20 mPa.s,11a surface tension value below 80 mN.m-1,14-16 stability of the ink in solution/suspension in the printhead, and the particle size of the ink constituents preferably well below (by orders of magnitude) the nozzle orifice.11cThese values are just guidelines and the particular values may vary from system to system. The particle loading is also a key factor in determining the stability of the printing process.

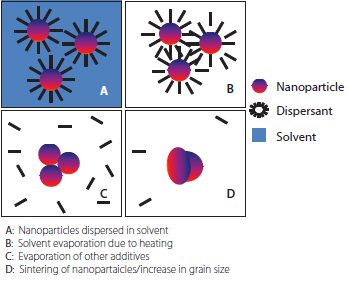

Sintering/Curing: Unlike graphical printing, where the functionality light absorption (hence: color) is more or less achieved immediately after the deposition process and drying of the layer, usage of functional inks “beyond color” requires a suitable transformation of the deposited ink layer to render it functional. This is done to remove the solvents and other additives such as surfactants, dispersants, humectants, adhesion enhancers, etc., which are present in the ink. In the case of (pigment-like) metal nanoparticle inks, for instance, the printed structure has to be sintered, so that the nanoparticles can join together and form a continuous percolating structure that allows for conductivity. For (dyelike) metal-organic decomposition (MOD) inks, the molecular complexes have to be broken up to enable formation of metal clusters. In both cases, sintering is then usually accomplished by the application of heat. To render the technique suitable for flexible plastic substrates that are thermally instable, other sintering techniques such as continuous,17-23 flash UV radiation,17-23 plasma treatment,17-23 or laser-assisted sintering,17-23 microwave-assisted sintering,17-23 DC or AC electric fields17-23 or chemical sintering12h have been proposed. The sintering sequence of a metal nanoparticle ink due to the application of heat is depicted in Figure 4.

Figure 4.Sintering sequence of a metal nanoparticle based ink.

The quality of sintering is an important issue. Due to the presence of residues, the printed structures are almost always less than 100% dense, even after sintering. Moreover, thermal sintering is not suitable for all types of substrates, as the sintering temperature is usually larger than 150 °C - many polymer substrates cannot withstand such temperatures. In the case of organic polymer inks, the printed structure is cured rather than sintered. Curing refers to the hardening of polymers due to cross-linking.

Application Examples

There are numerous application examples that demonstrate the suitability of inkjet printing for printed electronics; only a selected few are presented here.

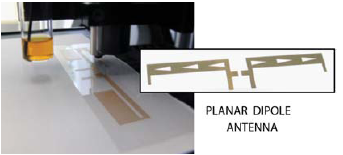

Figure 5 shows one such application: an inkjet-printed planar dipole antenna for ultra-high frequency (UHF) range, on flexible and rigid substrates.25 Filter, transmission line, and patch antenna for the same frequency range have also been inkjet-printed and reported.9,26

Figure 5.Inkjet printing of a planar dipole antenna with a resonance frequency of 868 MHz, using silver ink, at TU Chemnitz/Fraunhofer ENAS, Germany.

Inkjet printing has been successfully used to fabricate passive electrical components. It has also surpassed spin coating as an effective manufacturing method to fabricate organic or polymer light emitting devices (OLED/PLED). In fact, high-resolution patterning of an allpolymer thin-film transistor (TFT) using inkjet printing has already been achieved. However, these devices are currently restricted to low-end applications e.g., radio frequency identification tags (RFID), as the active materials they are made of have low mobility. Moreover, their switching speeds are low.27-28 Another active area of research is solar energy. Inkjet-printed organic solar cells were demonstrated by Konarka Technologies Inc. Research activities are currently underway to inkjet print high-efficiency solar cells using inorganic materials.28

Conclusions and Outlook

Inkjet printing holds a lot of promise to revolutionize the way electronics are manufactured. Even though there are not many products in the market that are fully inkjet-printed, efforts are well underway to surmount the challenges.

One of the most important factors that would play a decisive role in the success of inkjet printing in electronics applications is the advancement in materials development, that is, ink development. Inks containing functional materials that offer high performance such as high mobility, at lower sintering temperatures, besides reliably high printability will enable inkjet printing of high performance electronic devices on a variety of substrate materials. The success of inkjet printing might also depend on how quickly the alternative sintering and curing techniques mature, so that heat addition to the printed flexible substrate can be kept minimal. Finally, the resolution of inkjet printing, which is much lower than photolithography, will be a limiting factor in its application in high density circuit fabrication.

Materials

References

To continue reading please sign in or create an account.

Don't Have An Account?