3D Printing of Carbon Fiber-Reinforced Composites

How Are Carbon Fibers Used in 3D Printing?

3D printing is a type of additive manufacturing that can be used to rapidly fabricate components with highly customizable geometries, most typically using a layer-by-layer fabrication process. 3D printing is rapidly attracting growing interest from both the scientific research community and from those in manufacturing1,2 because of its potential for enabling low-cost, highly flexible, low- and mid-scale manufacturing. Thermoplastic materials, which can be melted and formed again into intended shapes, are currently one of the most commonly used materials in 3D printing. While these materials have gained widespread use in the production of prototypes, they typically lack the thermal, chemical, and mechanical stability required for use in the functional or load-bearing components required for industrial applications.2

Fiber-reinforced plastics (FRP) have recently gained attention for their potential use in 3D printing to enhance the mechanical strength and elasticity of manufactured parts.3-4 These composite materials can match the strength of many metals but at much lighter weight. In particular, the addition of carbon fibers to plastic resins is becoming a widely used strategy to enhance the mechanical properties of 3D printed parts.

Advantages of Carbon Fiber-Reinforced Plastics:4

- High tensile strength

- Chemical resistance

- Stiffness

- Temperature tolerance

- Low thermal expansion

Expanding Applications of Carbon Fiber-Reinforced Plastics

A number of companies are already commercializing 3D printers and printable materials dedicated to producing carbon fiber-reinforced composite parts for customers in various industries.5 Currently, 3D printed parts made out of carbon fiber-reinforced composites are used in the design and construction of race cars, drones, high performance sporting equipment, and many other applications that require lightweight but strong materials to boost product performance.5,6

3D Printing Processes for Carbon Fiber-Reinforced Plastics: FDM vs. SLS

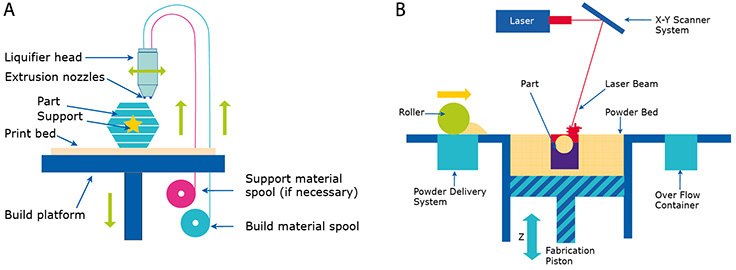

Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) are two 3D printing processes that are widely used to create functional parts using carbon fiber-reinforced materials as feedstock. FDM is a process that builds plastic parts using layer-by-layer extrusion of heated filament materials (Figure 1a).7 SLS, on the other hand, is a process to fabricate parts by building successive layers made out of laser sintered powder materials (Figure 1b).8 Depending on the processing conditions and design requirements of the finished parts, post-process treatments such as heating can be required.7

Figure 1.a) Illustration of FDM process, b) Illustration of SLS process

Materials Required for Preparing Carbon Fiber-Reinforced Composites for 3D Printing

Depending on the design requirements of the finished products and research interests, different types of plastic resins, and carbon fibers can be selected to make composite materials suitable for 3D printing.

The mechanical strength of the finished product is heavily influenced by the types of plastic resin selected, as well as the length and loading of the carbon fibers.7,8 For example, researchers have reported using carbon fibers (150 µm/ 100 µm) as reinforcing materials to improve the mechanical strength of ABS thermoplastics. The resulting composite, with 5 wt% carbon fibers, showed >20% increase in Young’s modulus and tensile strength.7

Carbon nanomaterials, such as carbon nanotubes and graphene, have unique physical and chemical properties that can enhance the tensile strength and thermal stability of plastic materials.9

Carbon nanofibers

Carbon nanotubes and graphene

Methods for Preparing Carbon Fiber-Reinforced Composites

To render the composite materials suitable for the FDM process, carbon fiber and plastic resin pellets are compounded in a blender/mixer to produce a mixture of carbon fiber and plastic resin. Next, the mixture is fed into an extruder to produce the filament used in the FDM process (Figure 2a).7 To prepare materials for the SLS process, carbon fiber and plastic resin materials are first dissolved in an organic solvent to make a homogeneous mixture. This solvent is then removed to precipitate out the powder, which is composed of carbon fiber and plastics. The powder is further crushed and milled before it is used in the SLS process (Figure 2b).8

Figure 2.a) Illustration of materials preparation for the FDM process, b) Illustration of materials preparation for the SLS process.

Carbon fiber- and carbon nanotube-reinforced materials

To continue reading please sign in or create an account.

Don't Have An Account?