Select a Size

About This Item

InChI

1S/3ClH.Ru/h3*1H;/q;;;+3/p-3

SMILES string

Cl[Ru](Cl)Cl

InChI key

YBCAZPLXEGKKFM-UHFFFAOYSA-K

assay

40-50% Ru basis (gravimetric), 99.99% trace metals basis

form

powder

reaction suitability

core: ruthenium

greener alternative product characteristics

Catalysis

Learn more about the Principles of Green Chemistry.

sustainability

Greener Alternative Product

specific gravity measuring range

6.97 g/mL

impurities

≤150 ppm (trace metals analysis)

color

dark gray to black

pH

1-2

solubility

water: soluble

density

3.11 g/mL at 25 °C (lit.)

application(s)

PEM fuel cells

homogeneous catalyst

material synthesis precursor

greener alternative category

Quality Level

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

signalword

Danger

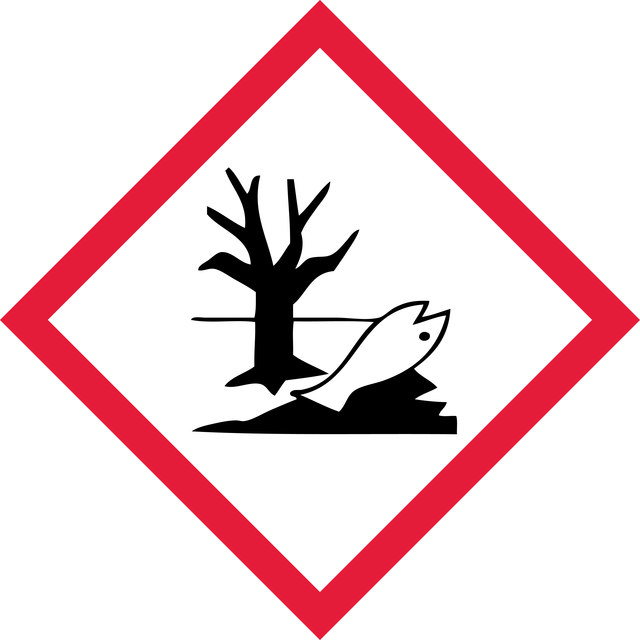

hcodes

Hazard Classifications

Acute Tox. 4 Oral - Aquatic Chronic 2 - Eye Dam. 1 - Skin Corr. 1B

Storage Class

8A - Combustible corrosive hazardous materials

wgk

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Discover the ways in which high-purity metal salts improve the selectivity, yields, and catalytic efficacy of organic synthesis reactions.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service