Sign In to View Organizational & Contract Pricing.

Select a Size

About This Item

NACRES:

NA.23

UNSPSC Code:

12352300

form

liquid

color

orange-red

pH

<1

Looking for similar products? Visit Product Comparison Guide

General description

Room-temperature nickel metallizing (RTM) process for alumina ceramics and other dielectric materials - strongly bonded nickel can be plated, soldered, brazed or welded.

Application

- The RTM process is applicable to metallizing alumina substrates in hybrid and microcircuits, insulated heat sinks, ceramic tubes, windows and terminals. Strong bond structures are produced. Structures with hermetic seals are formed as well.

- The RTM process is also useful for metallizing barium titanate and ferrites. In addition, many polymeric materials, notable polyesters, epoxies, cellulosics, mylar and acrylonitrile-butadiene-styrene (ABS terpolymer) may be metallized following suitable modifications of the etch (Solution A).

- RTM lends itself productively to the application of photolithographic technology using photo resist materials to register metallization patterns. In this manner, conductive pads may be formed for thin film and hybrid circuits. Base plates for building capacitor structures are also quite feasible.

Features and Benefits

UNIQUE FEATURES:

The RTM process offers a reliable, yet simple and economical method to metallize dielectric (non-conductor) materials at room temperature. This metallizing process with nickel is especially suited for commercial alumina type ceramics. The process sequence in 5 basic operations is illustrated above.

Pretreatment of the ceramic material with Polimet lapping compound may be omitted if the ceramic material already shows surface roughness of at least 20 microinches, average. Surface lapping with Polimet compound will result in a uniform surface with a roughness of 25 microinches average.

The composition and formulation of A-B-C-D solutions used in RTM permit excellent control of the metallization process.The nickel deposit is found to be unstressed, highly conductive, and extremely adherent with strong bond strength exhibited from −60 °C to + 850 °C. It has a hardness of at least 500 (Vickers) as deposited. The adherent nickel deposit may be plated, soldered, brazed or welded.

- Low cost metallization process.

- Excellent bond strength − 100 psi typical.

- Withstands temperature extremes - - 65 °C. to + 850 °C.

- Passes Mil specifications for temperature cycling and shock.

- Hermeticity - leak rate < 10-8cc helium/second.</LI>Permits registration of metallization patterns with good resolution using photolithographic techniques and mechanical masking.

- Process applicable to beryllia, barium titanate, ferrites, epoxies, mylar and other dielectrics.

The RTM process offers a reliable, yet simple and economical method to metallize dielectric (non-conductor) materials at room temperature. This metallizing process with nickel is especially suited for commercial alumina type ceramics. The process sequence in 5 basic operations is illustrated above.

Pretreatment of the ceramic material with Polimet lapping compound may be omitted if the ceramic material already shows surface roughness of at least 20 microinches, average. Surface lapping with Polimet compound will result in a uniform surface with a roughness of 25 microinches average.

The composition and formulation of A-B-C-D solutions used in RTM permit excellent control of the metallization process.The nickel deposit is found to be unstressed, highly conductive, and extremely adherent with strong bond strength exhibited from −60 °C to + 850 °C. It has a hardness of at least 500 (Vickers) as deposited. The adherent nickel deposit may be plated, soldered, brazed or welded.

signalword

Danger

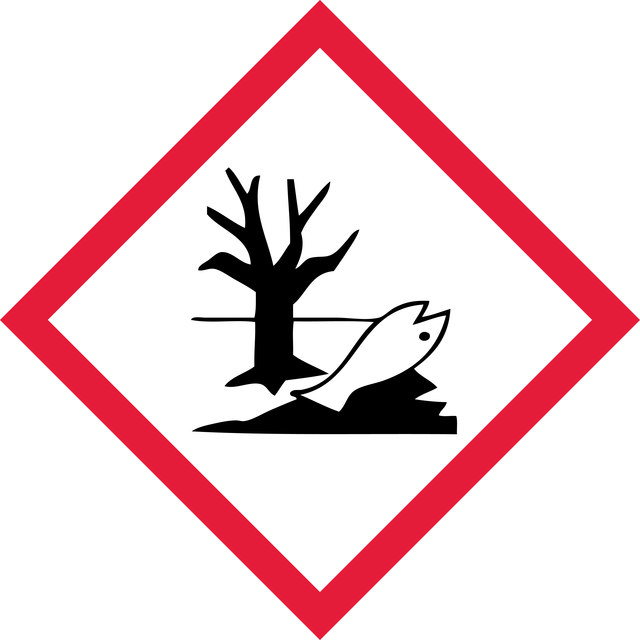

Hazard Classifications

Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Aquatic Acute 1 - Aquatic Chronic 1 - Carc. 1B - Eye Dam. 1 - Met. Corr. 1 - Muta. 1B - Repr. 2 - Resp. Sens. 1 - Skin Corr. 1 - Skin Sens. 1 - STOT RE 2 Inhalation - STOT SE 3

target_organs

Respiratory system

Storage Class

5.1B - Oxidizing hazardous materials

wgk

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Regulatory Information

新产品

This item has

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service