Sign In to View Organizational & Contract Pricing.

Select a Size

About This Item

NACRES:

NA.23

UNSPSC Code:

12352303

form

liquid

color

colorless

pH

7-9

Related Categories

General description

Bright electroless gold plating solution is formulated as a trouble-free gold plating solution designed to plate gold on metal parts by an electroless immersion process for printed circuit boards, transistor headers, electrical connectors, diode leads, lamps and other electronic parts. This process operates by the electroless displacement of base metals by gold, brought about by a difference in EMF potentials. Bright Electroless Gold is ready to use without modifications and will deposit gold on most common metals and alloys including copper, commercial brass, kovar, nickel, tin-lead solders, pure tin, iron and indium antimonide.

Application

- Metal parts to be plated should be thoroughly cleaned before use. The normal cleaning procedures for electroplating are adequate.

- Bright electroless gold plating solution will show a decrease in pH with use. The pH should not be allowed to deviate from the normal conditions for plating since inferior deposits result. Adjustment of pH can be conveniently accomplished by the addition of small amounts of ammonium hydroxide to raise pH or citric acid to lower it.

- The recommended plating temperature is 90 °C maximum for most metals. However, for tin-lead solders and pure tin, an optimum temperature of 50 °C is recommended.

Bright electroless gold plating solution can be used in the fabrication of electrical contacts in electronic devices. It can be used in the activation of aluminum alloy for complementary metal-oxide-semiconductor (CMOS) sensors. It can be electroplated on a polymeric substrate to fabricate ultra-light metallic micro-lattice materials.

Gold content: 1/3 troy ounce per gallon.

Features and Benefits

Features:

- Economical gold plating

- Plates bright gold on copper, kovar, brass, nickel, tin-lead solders and indium antimonide

- Excellent solution stability

- Operates with simple control of plating solution

- Ready-to-use - no mixing required

signalword

Danger

Hazard Classifications

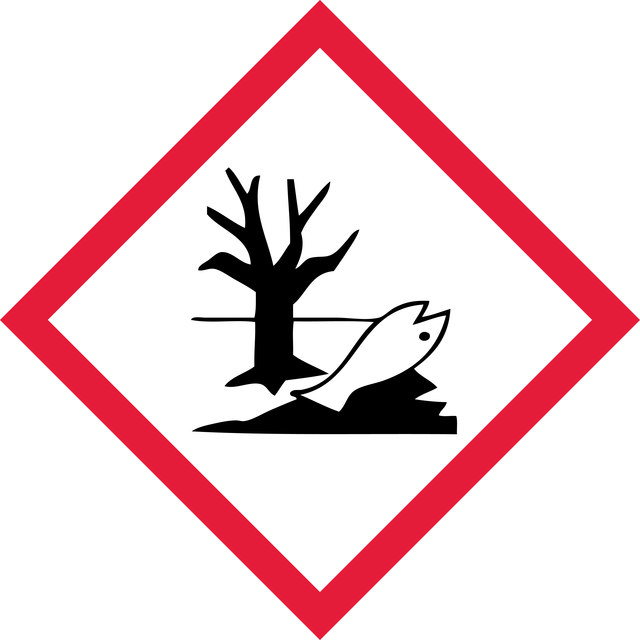

Acute Tox. 3 Dermal - Acute Tox. 4 Inhalation - Acute Tox. 4 Oral - Aquatic Acute 1 - Aquatic Chronic 2 - Eye Dam. 1 - Skin Corr. 1B - STOT SE 3

target_organs

Respiratory system

Storage Class

6.1B - Non-combustible acute toxic Cat. 1 and 2 / very toxic hazardous materials

wgk

WGK 2

flash_point_f

Not applicable

flash_point_c

Not applicable

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Electroless gold plating on aluminum patterned chips for CMOS-based sensor applications

Ko JW, et al.

Journal of the Electrochemical Society, 157(1), D46-D46 (2009)

A simple, highly efficient route to electroless gold plating on complex 3D printed polyacrylate plastics

Kim SH, et al.

Chemical Communications (Cambridge, England), 54(74), 10463-10466 (2018)

Development of new electrolytic and electroless gold plating processes for electronics applications

Osaka T, et al.

Science and Technology of Advanced Materials, 7(5), 425-437 (2006)

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service