Select a Size

About This Item

form

dispersion

concentration

2.5 wt. % (crystalline ZnO in α-terpineol)

work function

-4.1--4.5 eV

color

translucent brownish

particle size

8-16 nm

viscosity

26-36 cP

Looking for similar products? Visit Product Comparison Guide

Application

Preparation Note

- Storage: In dark at room temperature.

- Prior to application: Shake, ultrasonicate with sonic horn and (optionally) filter through 0.45 μm PTFE filter.

- Post-treatment: Annealing of deposited ZnO films at >120°C.

Legal Information

signalword

Warning

hcodes

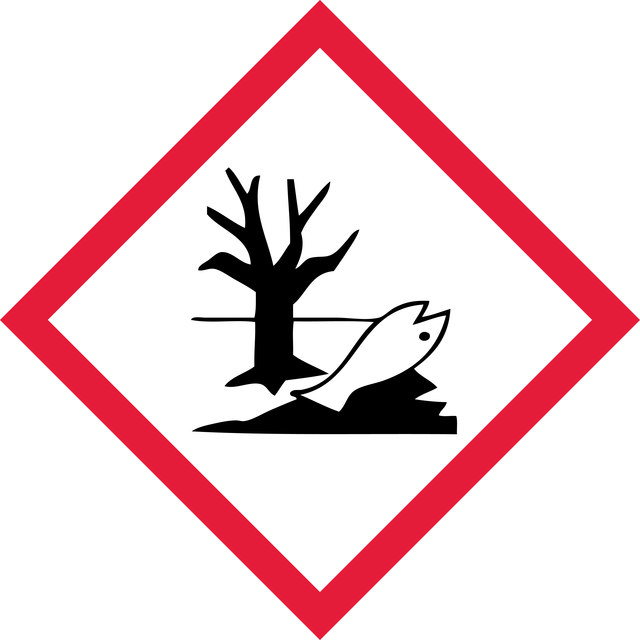

Hazard Classifications

Aquatic Chronic 2 - Eye Irrit. 2 - Skin Irrit. 2

Storage Class

10 - Combustible liquids

wgk

WGK 2

flash_point_f

197.1 °F

flash_point_c

91.7 °C

Regulatory Information

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Progress in solution-processed functional materials leads to thin-film optoelectronic devices for industrial and consumer electronics.

Professors Tokito and Takeda share design principles and optimization protocols for organic electronic devices, focusing on flexibility and low cost.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service