Select a Size

About This Item

InChI key

NKNDPYCGAZPOFS-UHFFFAOYSA-M

InChI

1S/BrH.Cu/h1H;/q;+1/p-1

SMILES string

[Cu]Br

assay

99.999% trace metals basis

form

powder

reaction suitability

core: copper, reagent type: catalyst

impurities

≤15.0 ppm Trace Metal Analysis

mp

504 °C (lit.)

density

4.71 g/mL at 25 °C (lit.)

Quality Level

Looking for similar products? Visit Product Comparison Guide

General description

Application

- As a solution-processable hole transport layer (HTL) for organic solar cells (OSCs). CuBr enhances the power conversion efficiency of solar cells.

- As a precursor to synthesize photoluminescent metal organic frameworks(MOFs).

- To synthesize highly emissive three-coordinate copper(I) complexes as a dopant in OLEDs with maximum external quantum efficiency of 21.3%.

- As a catalyst with ligands for atom transfer radical polymerization (ATRP) reaction of tertiary alkyl halides in 14 different solvents to determine the rate constant.

- To synthesize macrocyclic polymer via intramolecular radical trap-assisted atom transfer radical coupling.

signalword

Danger

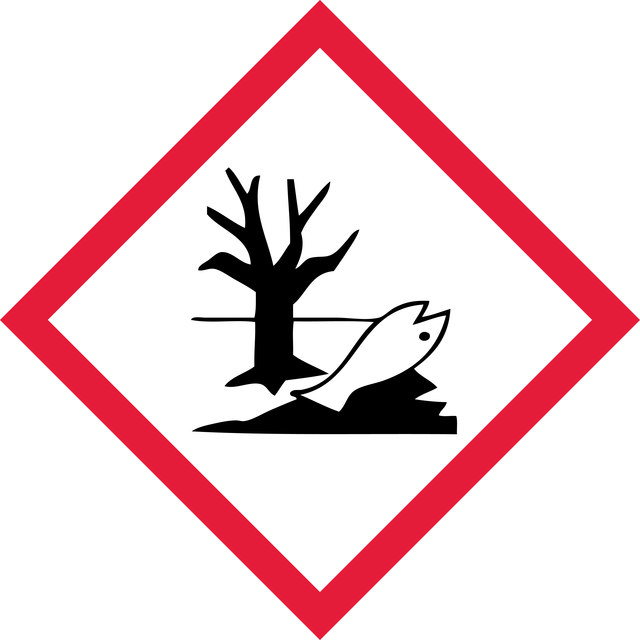

Hazard Classifications

Acute Tox. 4 Dermal - Acute Tox. 4 Oral - Aquatic Acute 1 - Aquatic Chronic 1 - Eye Dam. 1 - Skin Irrit. 2

Storage Class

11 - Combustible Solids

wgk

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

ppe

Eyeshields, Gloves, type N95 (US)

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Micro review of reversible addition/fragmentation chain transfer (RAFT) polymerization.

Protocols

We present an article about RAFT, or Reversible Addition/Fragmentation Chain Transfer, which is a form of living radical polymerization.

Polymerization via ATRP procedures demonstrated by Prof. Dave Haddleton's research group at the University of Warwick.

We presents an article featuring procedures that describe polymerization of methyl methacrylate and vinyl acetate homopolymers and a block copolymer as performed by researchers at CSIRO.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service