Chromolith® Columns: High Performance at Low Pressure

If you use traditional particulate separation columns when working with high-performance liquid chromatography (HPLC) in research and industry, you need high pressures of up to 1400 bar. But these high pressures are not necessary when using the special Chromolith® columns from the Supelco® portfolio, which are made of one continuous piece and allow for high-level and rapid separation performance with relatively low column back pressure. They are manufactured exclusively in Darmstadt, Germany

Whether dealing with insecticide residue in honey, artificial coloring in orange juice, or drug purity, chromatographic separation methods are indispensable in many areas of research and industry. High-performance liquid chromatography (HPLC) has become the most frequently used analytical method.

What makes HPLC so special? Extremely fine particles in the separation material ensure high separation performance. The finer the separation material – known as the stationary phase – the better the separation performance. And that is exactly where the challenge lies, because finer material also means smaller spaces between particles. This increases the pressure generated in the "mobile phase" for separating the substances to be analyzed.

“300 bar or more happen easily in rapid high-performance separation with very small particles,” explains Petra Lewits, a product manager responsible for this part of the Supelco® portfolio in the Life Science business of Merck. “Even up to 1400 bar is possible. But at one point you reach a limit, because that continuous, very high pressure puts a strain on the whole system. Columns with small particles get clogged relatively quickly. This has a significant negative effect on column life-time and cost of analysis” says Lewits.

However, there is a solution that makes it possible to overcome this limit. Instead of using columns with finer and finer stationary phases, one can use a monolith, a separation column that is made of one continuous piece. When the first models were released in the 1990s, the separation performance was still too low. This changed once Japanese researcher Kazuki Nakanishi succeeded in manufacturing a monolith from silica gel. However, chemical expertise was not enough to get the product to market. He needed support from the industry. Karin Cabrera, who was working on new chromatography materials in R&D at Merck at the time, became aware of the situation. Cabrera, who holds a doctoral degree in chemistry, recognized the product’s great potential and got in touch with colleagues at Kyoto University.

Figure 1 .Dr. Karin Cabrera, Dieter Lubda and their team with “their” Chromolith® separation columns. Source: 100 years of chromatography at Merck

The chemistry behind the formation of silica gels was not a big secret. But the requirements for manufacturing a separation column from one continuous piece are what differentiates this process from the conventional one. The monoliths are formed in specially prepared gelation tubes which then create the desired cylindrical shape. A different gelation tube is used for every size of HPLC column.

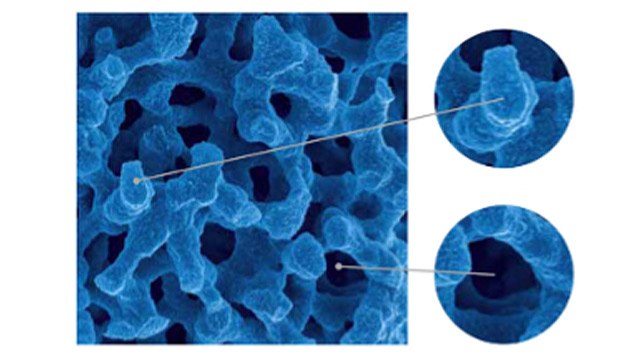

The size of the macro pores is determined using polyethylene oxide. The meso pores, which are about a hundred times smaller, are then formed on the surface of the silica gel. They are then used to separate the mixture of substances.

Figure 2 .Small meso pores along with macro pores, which are about 100 times larger, in a Chromolith® column.

However, first a crucial problem needed to be overcome. For the monoliths to be used in HPLC, they need to be sufficiently stable in the presence of both pressure and solvents. Merck developed a special process just for this, one in which the monoliths were coated with high-performance plastics. Benjamin Peters, Karin Cabrera’s successor, explains: “Coating is the most difficult step and is at the heart of manufacturing the Chromolith® columns. To date, none of our competitors have managed to put a comparable coating around silica gel monoliths.” And so, even after twenty years, this special process is unique to the Supelco® Portfolio of analytical products.

To continue reading please sign in or create an account.

Don't Have An Account?